New dosimeter design for FCC

The presence of radiation at the LHC may cause damage to sensitive electronics equipment and magnets, jeopardising the operation of the world’s largest and most complex machine. Until now, CERN radiation experts have been using state-of-the-art dosimeters to monitor radioactivity levels in the tunnels and to perform irradiation tests of electronics prior to their installation. However, a future circular collider such as the FCC, reaching collision energies of 100 TeV, is expected to generate unprecedented amounts of radiation posing new challenges for radiation monitoring. Specifically, it calls for the development of new technologies and materials, as current silicon-based dosimetry systems are not capable to withstand the new environment and fulfil the FCC requirements for ultra-high dose and fluence monitoring.

Georgi Gorine, a PhD student who divides his time between CERN and EPFL, studies how the existing irradiation testing facilities at CERN could be adapted to evaluate the systems and components designed for the FCC study. Moreover, under the supervision of Federico Ravotti (CERN) and Jean-Michel Sallese (EPFL), he is developing a smart radiation sensor for FCC that could be used as a dosimeter dosimeter for both Ionizing and Non-Ionizing radiation in the upgraded irradiation testing facilities, as well as in the accelerator itself.

As a possible new technology for FCC-level Non-Ionizing radiation monitoring, the team has proposed the novel idea to use metal thin films. Firstly, metals are known to be insensitive to low particle fluence (where current silicon-based devices saturate). Secondly, previous studies on radiation effects have demonstrated the variation of several properties of the metal (chemical, mechanical, transmutations, etc.) due to very high particle fluence. Among these, an increase of the metal resistivity was documented. With such idea, the team is developing a novel Radiation Dependent Resistor, where the sensitivity to particle fluence in terms of resistivity variation is selected by means of different metal layer geometry.

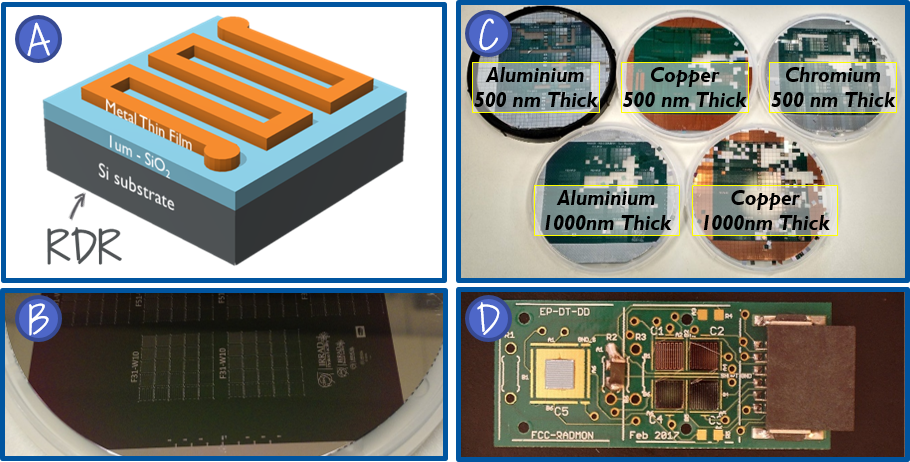

Figure 1: A) Schematic view of the novel Radiation Dependent Resistor (RDR); B) Picture of one of the produced 100 mm wafers; C) Picture of the 5 produced and diced wafers. D) The new FCC-RADMON printed circuit board with 5 wire bonded RDRs and one temperature sensor.

Presently, Georgi develops the first prototype of an ultra-high fluence sensor at the cleanroom facilities of the Centre of Micronanotechnology (CMi) in the École polytechnique fédérale de Lausanne. The proposed sensor, shown in Figure 1.A, is called Radiation Dependent Resistor (RDR) and is made by sputtering and consecutive lithography of thin layers of metals into “serpentine shaped” resistive structures as shown in Figure 1.B. For the first test, as shown in Figure 1.C, five wafers with three different metals (Copper, Aluminium, and Chromium) and different thicknesses (500 nm and 1000 nm) were produced with up to 300 devices on each. Each device was designed with a different number of fingers (the serpentine-like shapes, from 7 to 51 turns) and with increasing width (from 2 um to 50 um). Selected chips were then wire bonded on a dedicated FCC-RADMON printed board circuit (Figure 1.D), ready for the online resistivity measurement during the irradiation tests.

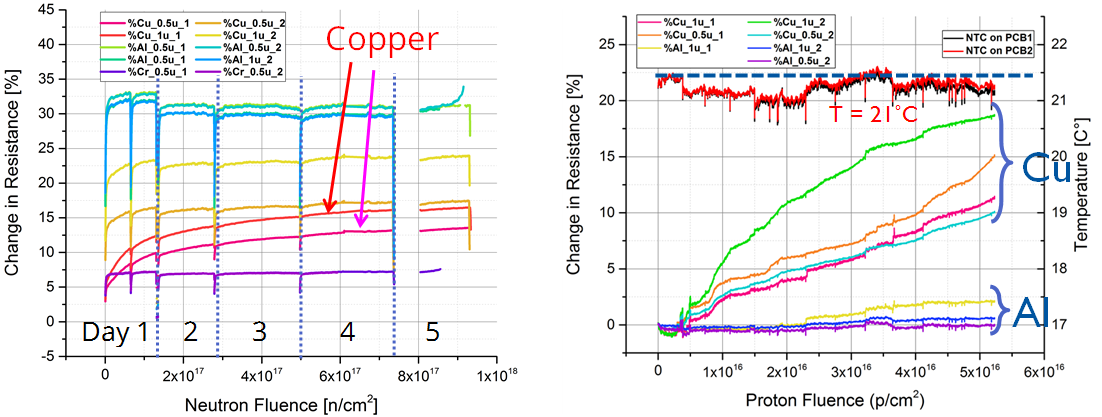

Figure 2: Left) Resistance variation from the initial value in % vs. the integrated neutron fluence. Strong temperature-dependent variation (65˚C in the irradiation channel) is responsible of the increase of all the dosimeters, but only Copper samples have shown a monotone increase of resistivity with increasing fluence. Right) Resistance variation from the initial value in % vs. the integrated proton fluence over 3 months of irradiation (left y-axis). On the right y-axis, the on-board temperature as measured by the two NTC installed on each PCB.

First results on the performance of the newly designed dosimeter (shown in Figure 2) were obtained during a 5-day campaign with a neutron flux of < 1018 n/cm2, a value which is close to the projected operating conditions of the FCC. All devices presented an increase of resistance, induced by displacement damage, although only Copper samples have shown a permanent variation, while the other resistivity variations were dominated by the drastic temperature increase inside the irradiation channel (>65˚C). This increase was not permanent in the case of the aluminium and chromium samples. However, the two copper samples yielded promising results, as they have not shown a big annealing after irradiation, thus integrating a fluence up to 9 x 1017 n/cm2 before failing.

These results were confirmed in a second irradiation experiment in the PS-IRRAD proton irradiation facility at CERN. The same set of FCC-RADMON PCBs were installed in June 2017 and are integrating particle fluence since then. The results of the first three months of irradiation (up to 5.2 x 1017 p/cm2) are shown in Figure 2.B on the right. Chromium samples were not irradiated in this test, while Copper and Aluminium have both shown a significant increase of resistivity with increasing proton fluence. Once again Copper samples have shown the greatest sensitivity, and among them, the samples with more fingers (31 vs. 13) and thinner ( 30 um vs. 40 um), are the ones with the largest signal.

Many theoretical reasons can explain these results, but they all seem to support the original proposal for using thin metals RDRs for the Ultra High Fluence Dosimetry. A post-irradiation analysis of the samples will allow to further evaluate the impact of different parameters. More irradiation tests will take place at the LHC and are undergoing in the IRRAD proton facility, using different particle species and different levels fluence, and a second production of only Copper samples will allow to further explore the sensitivity dependence upon geometry variation

This project will further evolve towards a complete FCC-RADMON monitoring system with the research and development of an Ultra High Dose Monitor based on thin-oxide and its rad-hard readout system.