The RD51 Collaboration: Development of Micro-Pattern Gas Detectors Technologies

Advances in photo-lithography and micro processing techniques during the past decade triggered a major transition from wire chambers to micro-pattern gas amplification devices such as GEM and MicroMegas.

Micro-Pattern Gaseous Detectors offer unprecedented spatial resolution, high rate capability, large sensitive area, operational stability and radiation hardness. The strong interest in the development and use of MPGD technologies led to the establishment in 2008 of the international research collaboration RD51 at CERN. Today, RD51 involves 84 Universities and Research Laboratories from 30 countries in Europe, America, Asia and Africa.The RD51 serves as an access point to the MPGD knowhow for the world-wide community; being a platform for sharing information, results and experience. In addition, RD51 optimizes the cost of R&D developments through sharing of resources, creating common projects and infrastructure.

The RD51 collaboration activities are transversely organized in seven Working Groups (WG) that cover all relevant topics of MPGD-related R&D. A number of tasks are assigned to each WG; for example, detector optimization, discharge protection, ageing and radiation hardness, optimal choice and characterization of gas mixtures and component materials, availability of adequate simulation tools, optimized readout electronics and readout integration with detectors, as well as production and industrialization aspects.Some of the Collaboration’s achievements are highlighted below:

MPGD technologies and new structures

Among the objectives of the Collaboration is the optimization of fabrication methods for MPGDs and the development of new multiplier geometries and techniques. One of the most prominent activities in this area is the development of large area GEM, MicroMegas and THGEM detectors. One decade ago the largest size of MPGDs was around 40 x 40 cm2, limited by existing tools, materials and fabrication techniques. A big step in the industrial manufacturing of MPGD’s with unit size of ~1 m2 and spatial resolution of 30-50μm- typical of silicon micro-strip devices , was the development of the new fabrication technologies like the single mask GEM and bulk MicroMegas.

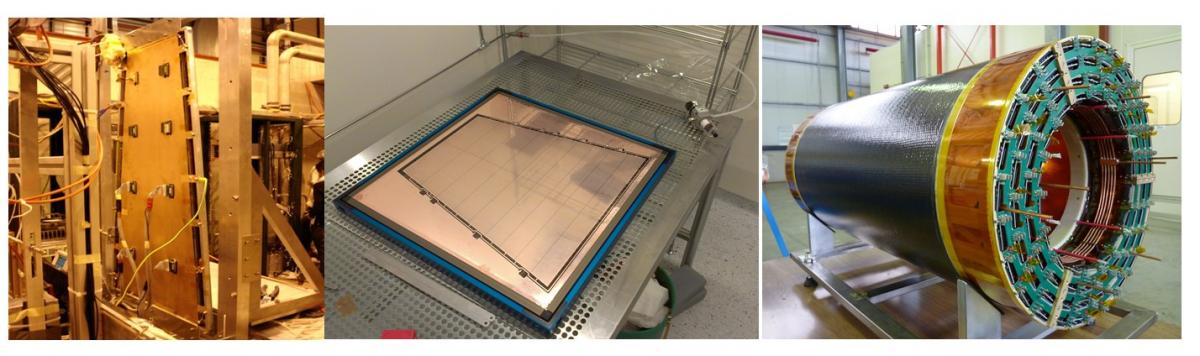

The standard technique for creating the GEM hole pattern was based on a very precise alignment of the two masks with accuracy of 5-10 μm that were limiting the achievable lateral size to 50 cm. This technology is now replaced by a novel single-mask technology. This technology simplifies the fabrication process to such extent that, especially with large production volumes, the cost per unit of area drops by orders of magnitude. The largest working prototype at present is a triple-GEM detector of 1 x 0.45 m2 size developed for the forward muon system upgrade in the CMS experiment.

The production of large MicroMegas often relies on the “Bulk” MicroMegas technique; an industrial assembly process allows regular production of large, robust and inexpensive detector modules. More recently, spark-protected MicroMegas were built by adding above the anode readout strips a layer of resistive strips, separated by an insulating layer. A rather advanced proponent of large resistive MicroMegas is the group working on an upgrade for the ATLAS forward muon spectrometer. The largest detectors built so far and operating smoothly have dimensions of 2.2 x 0.9 m2 with the potential to reach larger module sizes.

The principle of THGEM-based detectors is well established and recipesto build detectors satisfying all the major requirements have been worked out. Detailed R&D studies dedicated to explore the engineering aspects towards large size detectors are being pursued persuaded in the context of the upgrades of the COMPASS RICH-1 and the ALICE HMPID systems. A major concernis related to the industrial production of large size THGEM boards of the required quality.

Finally, recent aging studies performed by RD51 groups confirmed that the radiation hardness of MPGDs is comparable or superior to that of solid-state sensors used for tracking in harsh radiation environment.

To accommodate the development and prototyping (but not necessarily the mass production) of the large area MPGDs, the CERN TE MPE workshop has undergone an upgrade in 2010–2012.

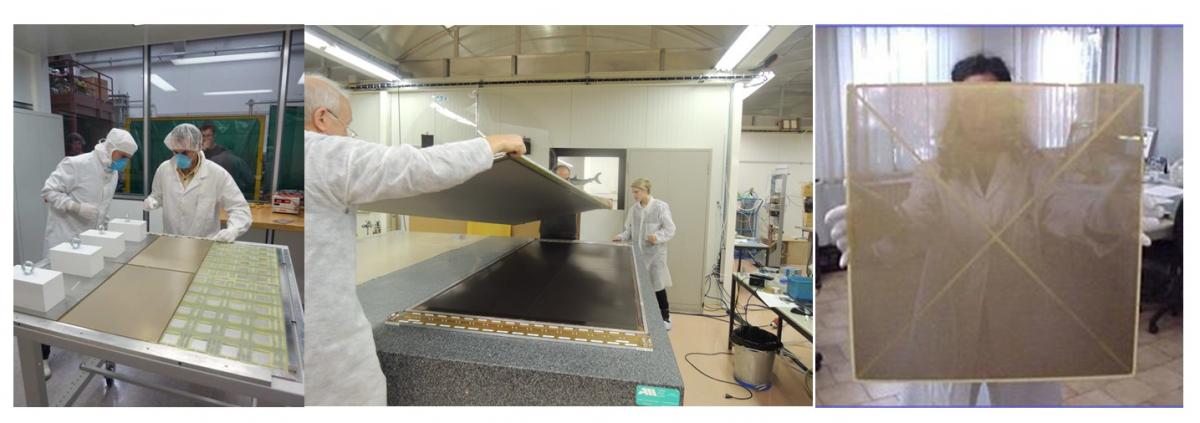

Left: Bulk MicroMegas 1 m2 module assembly for the Linear Collider DHCAL tests. Center: Resistive anode MicroMegas detector assembly for the ATLAS muon system upgrade. Right: THGEM module for the COMPASS RICH photo-detectors upgrade.

MPGD production facility and technology industrialization

A key point that must be solved to further advance cost-effective MPGDs is the manufacturing of large-size detectors and industrialization of the production (technology transfer). Nowadays, the CERN TE MPE workshop is a unique MPGD production facility, where generic R&D, detector components production and quality control take place. Following trends in the large detector units the RD51 collaboration, representing the needs of the community, proposed an extension of the workshop infrastructure needed to manufacture detectors with dimensions up to 2x1 m2, more than twice the maximum size of MPGDs produced at that time. Approved in 2009 by the CERN management the new MPGD facility will be able to produce 2x0.5 m2 single-mask GEMs, 2x1 m2 “Bulk” MicroMegas and 0.8x0.4 m2 THGEM detectors. This paved the way to the very promising R&D on the large area MPGD-based detectors, in view of large scape production in industry at a later stage.

Left: Single mask triple GEM detector prototype for the CMS high h upgrade project. Center: Single mask GEM foil before assembly into the detector module for the ALICE TPC end cap upgrade. Right: KLOE2 central tracker consisting of four layers of cylindrical single mask triple GEM detectors.

RD51 is also a reference point for firms that are interested in developing competences for MPGD manufacturing. As the technology matures for mass production and the technology transfer stabilizes, an increased number of industrial companies worldwide express their strong interest in MPGDs and have already produced series of prototypes: GEM (TechEtch, Scienergy, New Flex, Techtra), MicroMegas (ELVIA, ELTOS, Triangle Lab) and THGEM (Print Electronics, ELTOS). RD51 has developed close ties with some of these companies. It has signed license agreements and has engaged in a technology transfer program.

The aim of RD51 is to provide qualified industrial production facilities for GEM, MicroMegas and THGEM detectors, not only in view of the upgrades for the LHC experimentsbut also for the benefit of other physics programs performed worldwide and exploit the potential commercial applications that may arise.

Common software and simulation tools

Fast and accurate particle physics simulation becomes increasingly important as the complexity of instrumentation increases. The RD51 supports development of software focusing on the modeling of MPGDs as well as on fundamental aspects of gas detector simulation. A mature range of software tools is available for simulating primary ionization (Heed), electron transport properties in gas mixtures in electric and magnetic fields (Magboltz), and gas avalanches and induction of signals on readout electrodes (Garfield). It should be noted that Garfield has interfaces to Heed and Magboltz and needs to be supplied with a field map and detector configuration.

The main difference between traditional wire-based devices and MPGDs is that the electrode scale (10 mm) in MPGDs is comparable to the collision mean free path. Simulating processes in these detectors require an integrated approach of field calculations and charged particle transport since the field changes substantially over the free path between collisions. A field map can be generated by commercial finite-element method (FEM) programs like Ansys, Maxwell, Tosca, QuickField or Femlab. An open-source field solver is developed within the RD51 collaboration and the collaboration recently released neBEM a version of this software. The name was given from the fact that the software is based on the boundary element method (BEM). In many aspects the new package is superior to FEM solvers that are used for gas detector simulations. The Garfield++ package allows detailed simulation of small-scale structures.

Major efforts within the RD51 are devoted in the modeling of MPGD behavior for particular applications. For example, the difference in electron transparency between a MicroMegas mesh made of square and of round wires is now understood: Detectors like GEM are affected by surface charge produced in the avalanche and diffusion-deposited on the dielectric. This creates field distortions, which affect the transparency and gain and adversely affect the particle identification capabilities of the detector. Significant progress has been made in simulating GEM charging-up processes and ion back flow for TPC applications in view of ALICE TPC upgrade.

Electronics

The advances in the front-end electronics and data acquisition systems for MPGDs, modern gaseous detectors with CMOS pixel readout and discharge protection strategies are among the major tasks of the RD51 Collaboration. An important mission of the RD51 collaboration was the development of a portable multi-channel readout DAQ system of scalable architecture. Initiated in 2009, the so-called Scalable Readout System (SRS), has evolved into an open standard supported by many RD51 groups, contributing to SRS hardware, firmware, software and applications. It facilitates the access to an “easy-to-use electronics” with an associated readout, both for small R&D projects and LHC-like experiments, avoiding parallel developments of similar systems.

A main feature of SRS, apart from its scalability, portability and affordable cost is the free choice of the front-end ASIC (APV, VFAT, Beetle, VMMx, Timepix). More than 40 groups within the RD51 community have already expressed interest in SRS for MPGD applications in basic and applied research; recently, this system have been also used for readout of silicon photo-multipliers and is now available from the CERN Stores.

Left: Simulation of the avalanche development and charge carriers trajectories in the GEM detector using GARFIELD++ software package. Center: Scalable Readout System developed within RD51 Collaboration. Right: One of the RD51 trackers during the test beam campaign in the SPS North Area.

Common test beam infrastructure

The development of robust and efficient MPGDs entails a significant investment for laboratory measurements and detector test beam activities to study prototypes and to qualify final designs -including integrated system tests- in order to understand their performance. A semi-permanent common test beam infrastructure has been installed at the H4 area of the SPS test beam line at CERN for the needs of the RD51 community, which includes DAQ, services (mechanical supports, fiber optic lines, high voltage, signal and Ethernet cables) and gas distribution systems.

The H4 area has an advantage of the presence of the large area “Goliath” magnet (1.4 T), allowing tests of MPGDs in magnetic field. Three different high-precision telescopes are available at the RD51 test-beam facility and each consists of three tracking stations. Two devices are based on MicroMegas technology: “Bulk” MicroMegas (2.5 x 2.5 cm2) and resistive MicroMegas (10 x 10 cm2) and the third one is based on the triple-GEMs detectors (10 x 10 cm2). Software packages have been developed for data reconstruction, tracking and analysis of the data acquired with the trackers. Furthermore, the RD51 groups can use instrumentation, services and infrastructure of the CERN DT GDD laboratory. The SRS system, developed within the framework of the RD51 is available to the users both at the test beam and in the laboratory. Up to now, more than 15 groups regularly use general infrastructure during the annual test-beam campaigns; typically three periods of 1–2 weeks per year.

Summary

Since its establishment the RD51 collaboration consolidated world MPGD community and contributed to technological developments and applications of Micropattern Gaseous Detectors. It became common platform for sharing of information, results, and experience, and it supports efforts to make MPGDs suitable for large areas, create common infrastructure at test beams and irradiation facilities, increase cost efficiency, improve ease of use, help with the industrialization of the MPGD technologies.

In the next years, the RD51 will continue with its strong R&D program and with support of the LHC experiment upgrades and other HEP projects, focusing on the technology transfer, industrialization and applications.

Useful Links:

For more information you can visit The RD51 MOGD Collaboration website

MPGD2013: 3rd International Conference on Micro-Pattern Gaseous Detectors:

The 3rd International Conference on MPGD will take place in Zaragoza, Spain, on July 1-4, 2013 and will be followed by the RD51 Collaboration meeting on July 5-6. During the conference a review of the current status of the different MPGD technologies will be given, while recent R&D achievements, ideas for future developments and prospects for industrial production will also be discussed. For more details visit the conference web page http://gifna.unizar.es/mpgd13/

The International Organizing Committee:

A. Cardini (INFN Cagliari), K. Desch (U. Bonn), Th. Geralis (NCSR Demokritos Athens), I. Giomataris (IRFU Saclay), T. Kawamoto (ICEPP Tokyo), A. Ochi (Kobe Univ.) V. Polychronakos (BNL), A. Sharma (CERN), A. White (U. Texas Arlington), J. Wotschack (CERN).

The Local Organizing Committee:

I. G. Irastorza, J.A. Villar, G.Luzón, S. Cebrián, Th. Dafni, D. González‐Díaz, A. Ortiz de Solórzano (Technical support), J. Mena Alastuey (Technical support).