Scintillation light at the end of the tunnel

The LHC Long Shutdown 2 (LS2) is approaching in giant steps and with it the date for the installation of the LHCb upgrade detectors. A large SciFi tracker will replace the current downstream trackers SciFi stands for scintillating fibre and means that the fibres will produce tiny light flashes when they are traversed by charged particles like electrons, pions or kaons. The new tracker will use more than 10’000 km of scintillating plastic fibre to cover an area of about 340 m2 making it the largest SciFi tracker ever built. The fibres have a diameter of only 0.25 mm, enabling a detector resolution of better than 0.1 mm.

After being fabricated in Japan, the fibres spend most of their early life on travelling! First to CERN, where they undergo extensive quality checks, then to four winding centres located in Germany, Switzerland and Russia to be packed in 6-layer fibre mats, before meeting again either in Heidelberg or Amsterdam to form fibre modules and finally back at CERN for detector assembly.

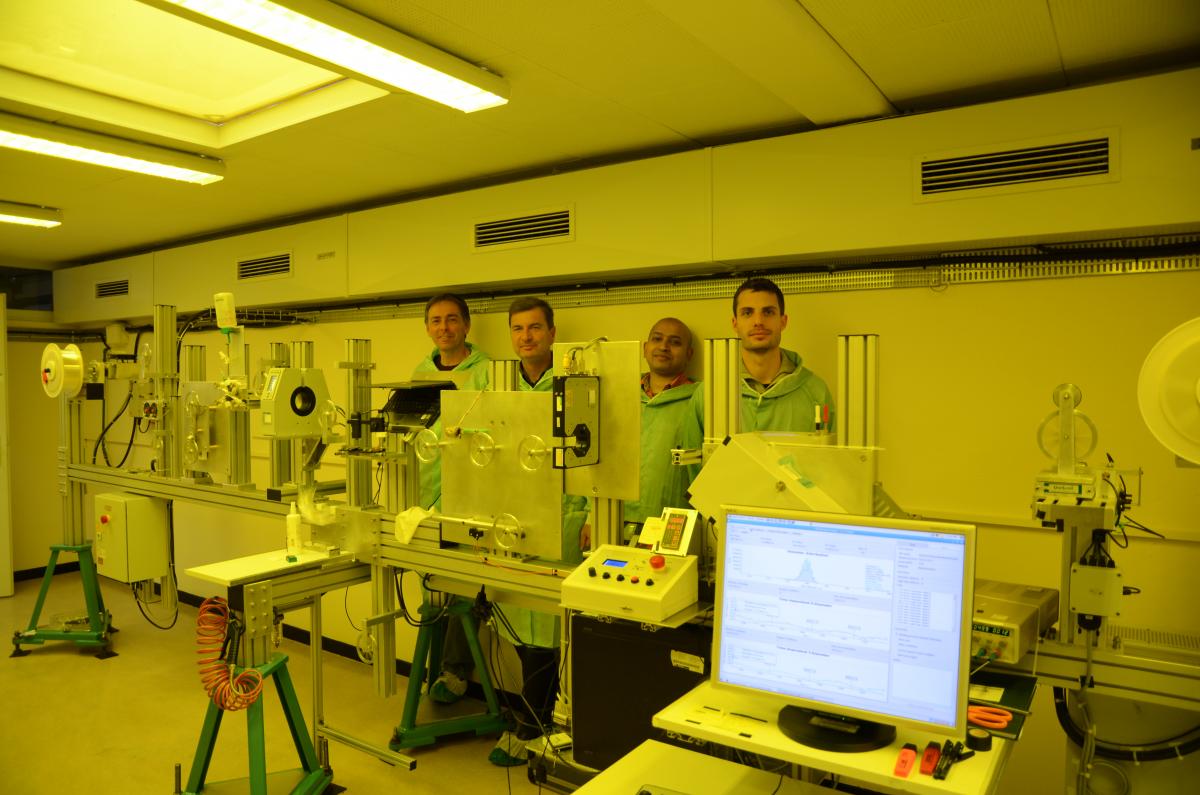

The SciFi scanning team behind the 6 meter long fibre scanning machine set-up at CERN. From left to right: Robert Kristic, Christian Joram, Biplab Dey, Lukas Gruber. Image Credits: CERN. (Note: the yellow colour fault on all the photos is due to the UV/blue filtering of the light in the SciFi labs in order to protect the fibres).

At present, the fibre quality assurance (QA) of the fibres at CERN is nearing completion. Three quarters of the 1’200 fibre mats have been wound and the first 20 modules have arrived at CERN (see a previous article in CERN Bulletin). After that, the fibres will be installed 100 meters underground, this will be the most sparkling part of their life as part of LHCb.

Within the last few years CERN’s main responsibility within the SciFi project was the R&D and QA of the scintillating fibres for SciFi, which started with the selection of the suitable fibre model and culminated in testing 11’000 km of fibre between May 2016 and December 2017. If it was in one piece, this fibre would be longer than the flight distance between the production site in Japan and CERN or one quarter of the earth circumference. To allow for reasonable packaging and shipping the fibres are delivered on about 900 individual spools, each about 12.5 km in length.

Bump removing section of the fibre scanner. If the fibre diameter exceeds 0.35 mm the fibre gets stuck in the hot tool, the rotatable arm moves up, stops the machine and slowly pulls the fibre through the conical tool with a tension of 100 cN (g). Image Credits: CERN.

Over the last 20 months the SciFi fibre team received 24 of these spools, i.e. 300 km of fibre, every two weeks. More than 1’500 fibre samples were evaluated to determine parameters like optical attenuation length, light yield and resilience against X-ray radiation and ensure that the delivered material fulfils the requirements. In addition, a fibre scanner was developed and built at CERN to precisely measure the fibre diameter and simultaneously monitor the surface quality. It is operated from 7 a.m. to 7 p.m. on workdays since almost two years without major interruptions to enable scanning of 11’000 km of fibre until end of 2017. A special feature of the machine is the possibility to shrink diameter excesses (“bumps”) larger than 0.35 mm that would potentially cause distortions in the 6-layer pattern of fibre mats. The simple but effective method is based on pulling the fibre through a conical tool which is heated to 100°C. Such bumps appear on average once every 1.5 km such that in total about 7’200 noticeable bumps were detected, out of which 90% could be handled successfully by the machine, whereas the rest had to be cut out manually. The ability to remove most defects “on the go” drastically simplified the life of the technicians at the four winding centres.

Diameter defect before (left) and after (right) shrinking. Image Credits: CERN.

Gluing of two fibre end pieces after cutting out a large diameter defect. Image Credits: CERN.

Already in spring next year, the first fibre modules together with photodetectors, front-end electronics, cooling and other services will be mounted in LHCb’s new assembly hall (B3852) on a 7 m high C-shaped frame, representing one twelfth of the complete SciFi tracker. These operations are very labour intense and we count at least 12 months before all 12 C-frames can be installed in their final position in the LHCb underground cavern. If everything goes to plan, our fibres will start to twinkle in 2020 and measure precise particle tracks in LHCb.