Asterix in Switzerland

This episode of the adventures of the winged-helmed Gaul was published in 1970 and foretold what would happen 28 years later, when the CERN microelectronics group (MIC at the time, now the ME section in EP-ESE) welcomed the arrival of its first X-ray irradiation system. The need for such equipment emerged with the approval of the LHC experiments, where the electronics components – and in particular the Application-Specific Integrated Circuits (ASICs) to be installed in the tracking detectors – are exposed to unprecedented levels of radiation. Commercial-grade electronics of the 90s could not survive in this harsh environment; thus ASICs had to be made radiation tolerant with a combination of manufacturing technologies and design techniques. This required a good amount of radiation testing during both the initial prototyping and the final qualification phase.

One of the effects detrimental to the performance of Integrated Circuits is the deposition of energy by ionization: radiation generates electron-hole pairs leading to the accumulation of charge and active defects in the materials composing the ASICs. This gradually modifies its electric characteristics until eventually the initial functionality is lost. LHC circuits had to be qualified to survive the accumulation of energy, called Total Ionizing Dose (TID) and measured in Gy or rad (luckily the conversion is easy: 1 Gy = 100 rad), that was predicted with complex simulations of the detector environment. The initial radiation tests were performed using large commercial gamma-ray irradiation systems based on 60Co radioactive sources, and MIC researchers needed to travel to Saclay, near Paris, transporting the samples and all necessary equipment to the irradiation facility. Needless to say, this was not really practical and allowed at best for 3-4 campaigns per year, but at least allowed for the evening discovery of the City of Lights, since it took days to reach the targeted TID levels.

As the initial ASIC prototype phase advanced, it became evident that a change of gear was needed in our testing capabilities. CERN was not the first to be in this predicament. Back in 1982, a publication by L.J.Palkuti and J.J.LePage from the company ARACOR (Ca, USA) introduced an X-ray irradiation system custom-developed for TID studies of semiconductor components, a system that was soon after commercialized by the same company. In 1997 CERN-MIC invited tenders for the supply of a similar system. ARACOR was the only bidder proposing an already assembled system for this purpose, but the bid was eventually won by SEIFERT, a company specialized in X-ray inspection equipment from Ahrensburg (DE) and willing to build a custom system matching specifications. That turned out to be a blessing: although SEIFERT was bought by General Electrics and then Waygate, the system can still be easily serviced while ARACOR is not in business anymore and their unique X-ray tubes are very hard to find.

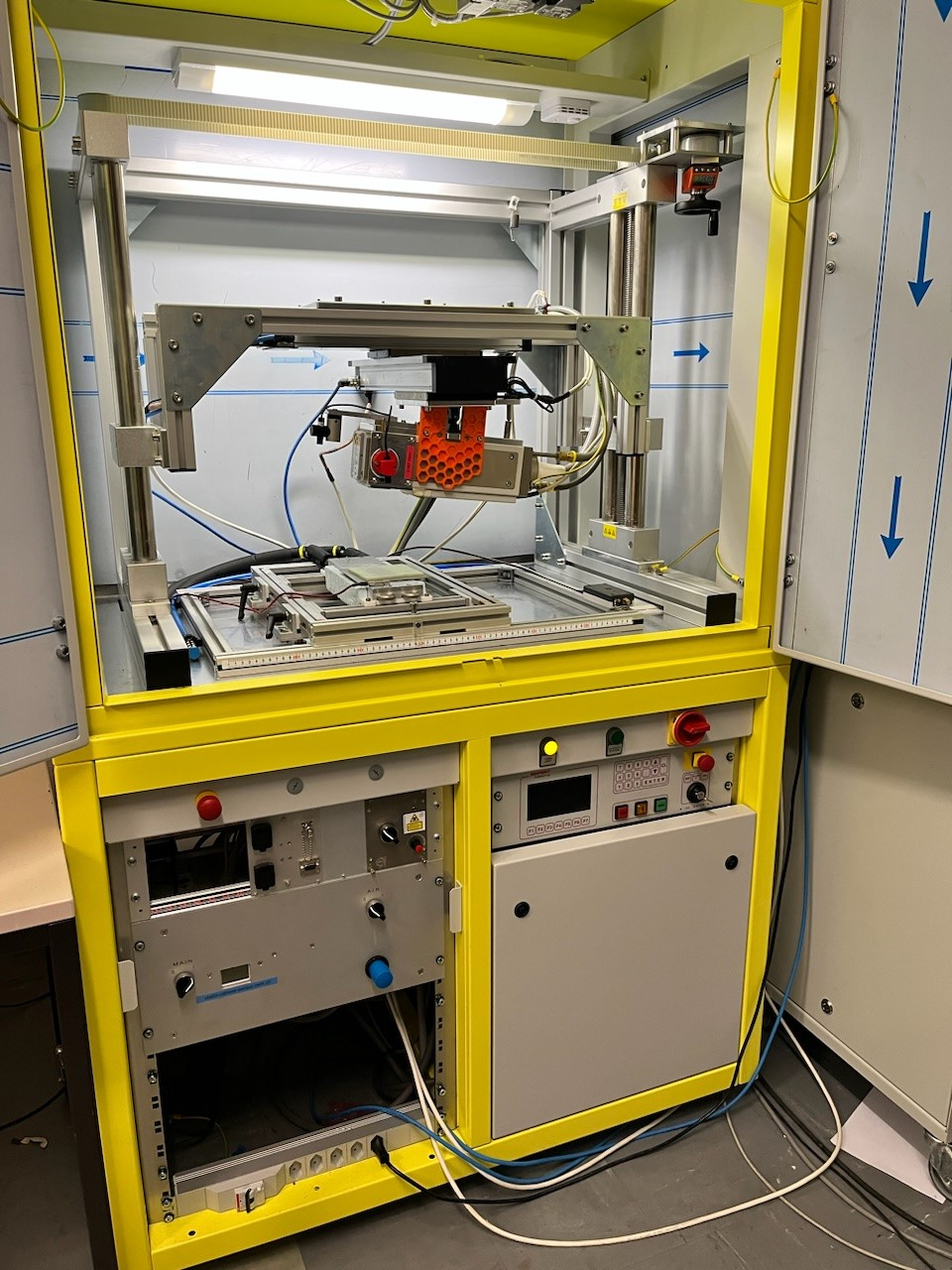

The first irradiation system was installed on the fifth floor of building 14 in 1998, the irradiation cabinet having to be fully disassembled to fit the small available lift. After 25 years of faithful service, and the occasional replacement of the high-voltage generator (up to 60kV are needed to accelerate electrons to the W target, eventually producing the X-rays) or the cooling system, the machine is still happily “roasting ASICs” today. SEIFERT could not deliver a device to measure the amount of dose deposited by the X-rays in the silicon ASICs, so the burden of finding a way to calibrate the system and know the dose rate (dose per unit time) fell on CERN. With the help of officials from RP and of a specialized company, it was possible to procure two diodes pre-calibrated to periodically measure the dose rate in different use configurations: different distance from the X-ray tube, different current and voltage settings. The machine was thus complete, and its use steadily increased in time, in particular when the HL-LHC upgrade program was launched and with it the need for a 10x higher tolerance to TID! Access to the irradiation system was organized via a web interface, and always extended to CERN collaborators from external Institutes. But with the sharp increase in the need, and the machine occupied 24-7, there was simply not enough capacity. This can easily be understood knowing that the irradiation of a single ASIC to the HL-LHC pixel detector requirements, 1Grad, takes at least 5 full days (and nights). The purchase of a second machine became a necessity, and in 2017 an almost identical system was purchased and installed (in 2018) close to the original one. This was configured slightly differently: with a larger beam size and without a wafer prober enabling testing of silicon wafers, this system was tailored to the irradiation of fully assembled ASICs. The necessity to name the two machines to easily distinguish them arose. The letter X, from X-rays, had to be used in the name and this led to the choice of AsteriX (the older machine, with smaller beam) and ObeliX (the new machine, with larger beam). This is how they are called in the dedicated web page that contains information and usage calendar: https://espace.cern.ch/project-xrayese. At the same time, new calibration diodes had to be procured to replace the original two samples after almost 20 years of use. A new diode model was found, and a global purchase and calibration was organized within ESE including colleagues in HEP from Institutes having X-ray machines: CERN-EP-ESE, CERN-EP-ADE where another X-ray machine is installed, INFN Padova (IT), USC Santiago de Compostela (ES), University of Glasgow (UK), INFN Genova (IT), KU Leuven (BE), ETH Zurich (CH), Technical University Graz (AT), University of Bonn (DE), INFN Torino (IT), Rutherford Appleton Laboratory (UK). All these Institutes now have identically calibrated X-ray systems, so studies performed in different locations can directly be compared.

ObeliX is one of the two X-ray irradiation systems in the CERN EP department, ESE group. The bottom picture shows the inside of the cabinet, where there is the X-ray tube.

After a few years of very intense usage, with both AsteriX and ObeliX used round the clock, the time for some rest for our valiant Gaul warriors has come, as we have recently observed a decrease in irradiation demands. This is a well-deserved partial rest: it is an obvious fact that they played a key instrumental role in the development and qualification of the radiation-tolerant ASICs for both LHC and HL-LHC. Thanks AsteriX and ObeliX for many years of intense efforts in defending our detector electronics village from the assaults of the radiation legions! We will keep your plate armours shining since we will continue needing you for the foreseeable future.