Mirror, mirror on the wall, who is the fairest of them all?

The mirror system is an important part of the NA62 RICH detector* covering the full acceptance range of 7m2 surface. It is composed of 18 hexagonal (Ø≈70cm, thickness 2.5cm) and 2 semi-hexagonal mirrors which are sustained by a lightweight support structure made of aluminium. The spherical shape of the mirrors reflects the photons - emitted by the decay pions and muons - onto 2000 photomultipliers situated 17m further upstream.

In spring 2014 all NA62 RICH mirrors were successfully coated in the Thin Film and Glass (TFG) lab of the PH-DT Group. Prior to the work on the final mirrors the team made a series of test evaporations to find the process parameters providing the highest reflectivity. A custom mechanical support was prepared to hold the large and heavy glass substrates inside the evaporation plant.

The TFG lab has a long-standing experience in mirror coatings for the UV wavelength range. The preferred process developed for such applications comprises three successive layers using Chrome, Aluminium and MgF2. Chrome is used as an attachment layer to the substrate, subsequent comes Aluminium providing the reflectivity and on top a transparent layer of MgF2 to protect the Aluminium against oxidation. In order to obtain excellent reflectivity the process optimisation is crucial, for example, the Al evaporation runs under maximum speed and is immediately followed by the application of the dielectric layer (MgF2).

The mirror substrates, produced by MARCON in San Dona/Italy, were fully characterized at INFN before shipping to CERN. In the TFG lab they were first thoroughly cleaned and inspected and then installed in the evaporation plant. During each evaporation a reference glass sample was added close to the mirror substrate for later quality control measurements.

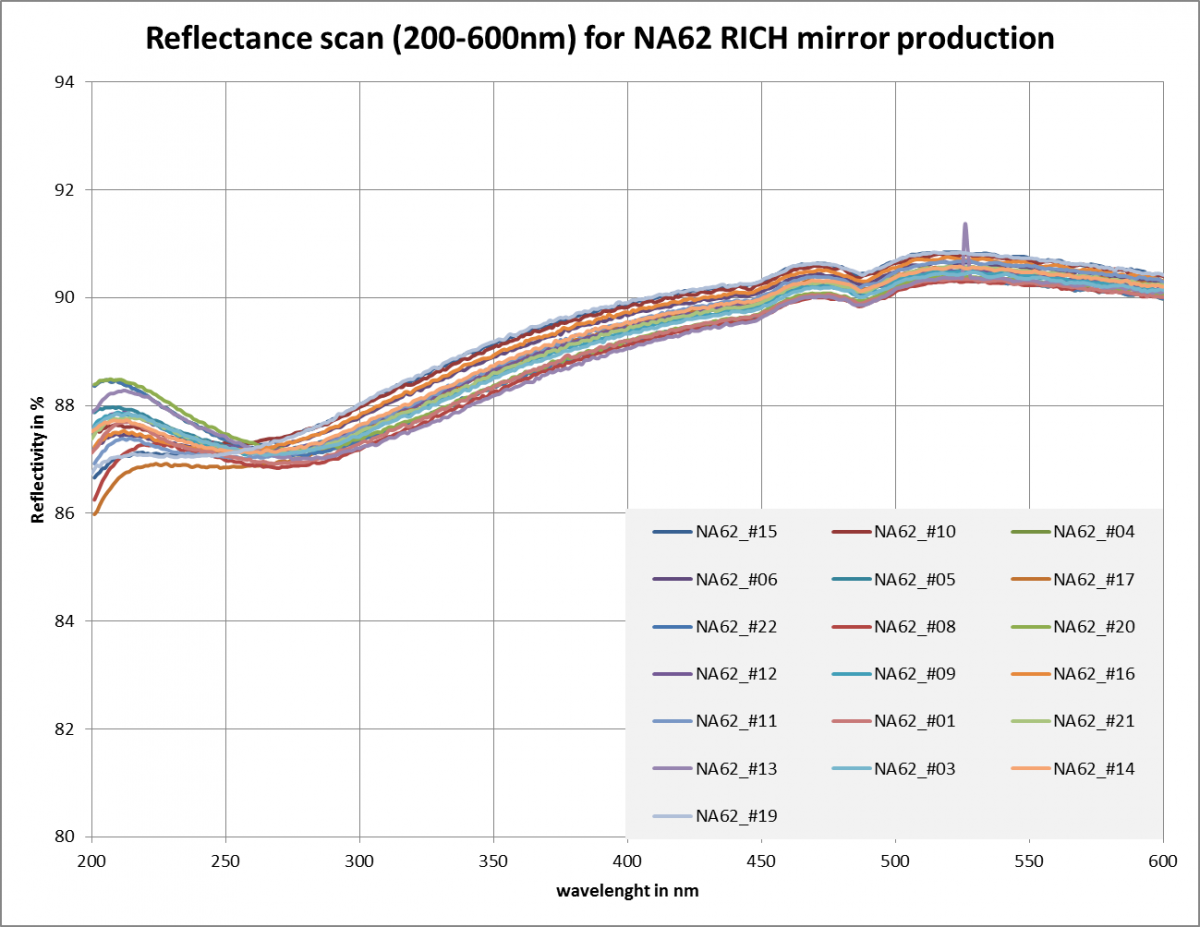

During the different evaporation steps (Cr/Al/MgF2) an INFICON® controller is used to regulate and monitor the thickness of the coatings. Since a recent upgrade the system permits data logging of all relevant parameters, i.e. layer thickness, vacuum pressure (outgassing) and temperature over time. This data helps to analyse and understand the individual processes. When the evaporation is completed, the mirror is removed and inspected visually. Finally the mirror is properly stored in its foreseen mechanics and wrapped in a dry nitrogen-filled plastic bag. As final quality control the specular reflectance of the glass reference sample is measured between 200nm and 600nm. Analysis of the 18 hexagonal mirror evaporations proves the stability of the process and confirms a very good reflectivity over the full range (mean 88%).

Fig.1 : Reflectance scans of the 19 hexagonal mirrors (18 regular 1 spare)

The mirrors are being installed over the summer and will be used in the first physics run of NA62 this autumn.

The NA62 RICH Detector is a common effort of INFN and CERN.

You can see a photo-gallery of the NA62 RICH mirror coating procedure here