Next-Generation CO₂ Cooling Systems Powering the Future of ATLAS and CMS

Four CO2 cooling plants and accumulators in the service cavern of CMS in May 2025. (Photo by Jérôme Daguin)

During recent shutdown periods, CERN engineers and technicians — in collaboration with the ATLAS and CMS teams — began installing the first units of next-generation carbon dioxide (CO2) cooling plants and their accumulators in the underground service caverns of the two experiments. These new, more efficient systems will replace the older cooling circuits that use synthetic refrigerants, significantly reducing the environmental impact of detector cooling.

Installation at CMS began in October 2024 and is scheduled to continue until July 2025. At ATLAS, an initial installation phase took place during this year’s Year-End Technical Stop (YETS), with full deployment planned for the upcoming Long Shutdown 3 (LS3).

Each cooling plant, weighing approximately 5 tonnes, is a critical component of the High-Luminosity ATLAS and CMS upgrades, set to begin operations in 2030. Certain parts of the detector must be maintained at extremely low temperatures, as low as -40°C to ensure optimal performance. The new cooling systems will extract up to 550 kW of heat from the HL-LHC CMS upgrade detectors (Tracker, MIP Timing Detector, and High-Granularity Calorimeter) and 300kW from the HL-LHC ATLAS upgrade detectors (ITk and HGTD), all while keeping extremely stable temperatures in the detectors.

At the same time, the new systems will stabilize temperatures and eliminate the use of synthetic refrigerants with high Global Warming Potentials (GWPs). GWP is a measure of how much more heat a particular fluid traps in the atmosphere compared to carbon dioxide (CO2). For example, C₃F₈ has a GWP of 8,900, meaning it is 8,900 times more potent than CO2 in terms of heat retention.

These new systems mark a significant improvement over the current CO2 cooling setups, which remove just 15 kW of heat from the CMS pixel detector at –25 °C and 3 kW from the ATLAS IBL detector at –30 °C, while still relying on synthetic refrigerants in their primary circuits.

The new CO2 cooling systems represent a major leap forward in cooling capacity, operating near the temperature limits of CO2. They are the result of an eight-year R&D effort led by CERN’s EP-DT group, in collaboration with the ATLAS and CMS experiments. The systems are based on the 2PACL (2-Phase Accumulator-Controlled Loop) process, originally developed for the AMS-02 experiment aboard the International Space Station and later adapted for CERN particle detectors. However, the scale required for the ATLAS and CMS High-Luminosity LHC upgrades demanded a fundamental redesign of the original implementation.

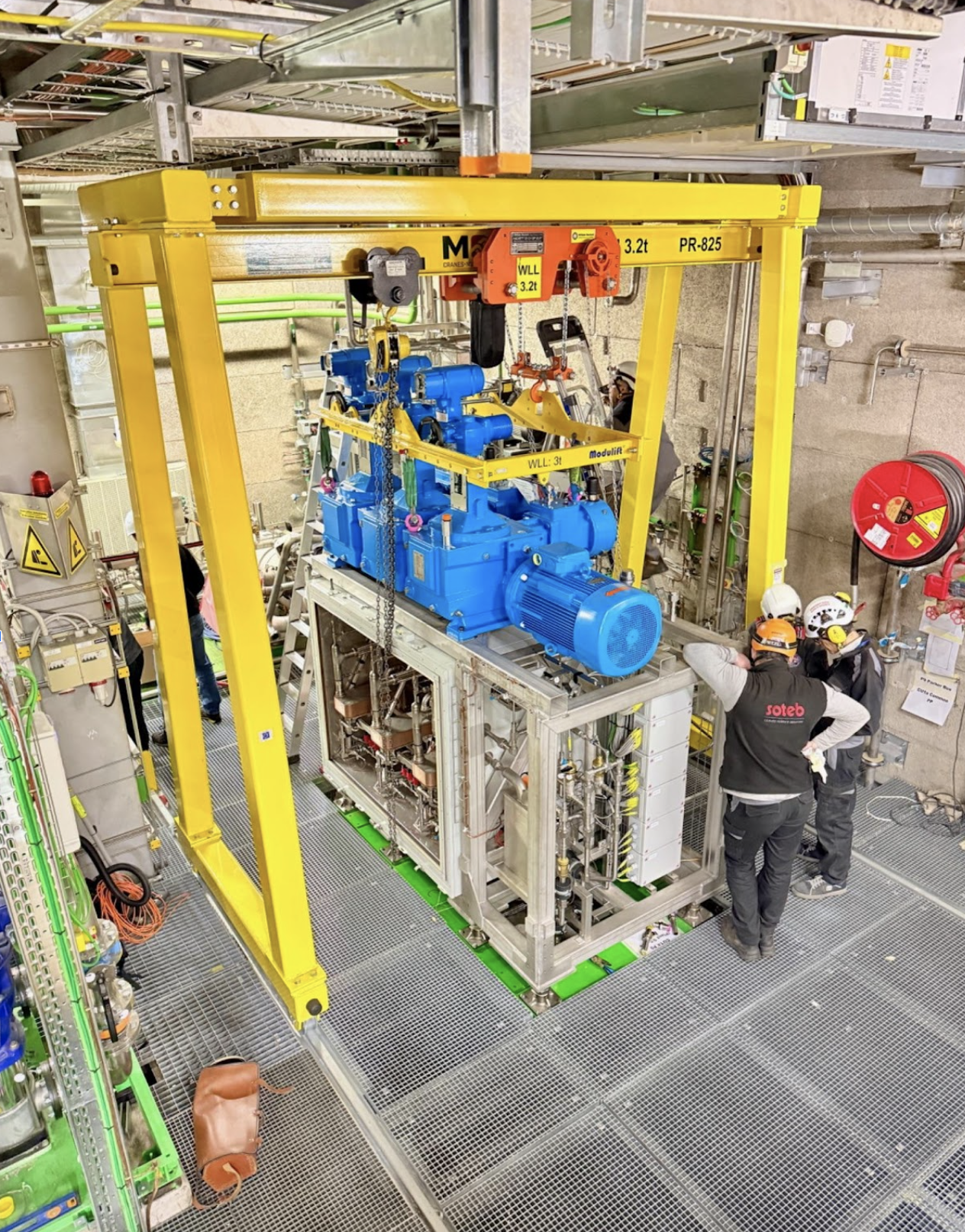

Installation of the first CO2 cooling plant in the service cavern of ATLAS. (Photo by Jérôme Daguin)

Once fully installed, the 2PACL systems will consist of nine cooling plants and eight accumulators (500-litre tanks that regulate the cooling process by controlling the pressure at which CO2 evaporates on the detector) in the CMS Service Cavern and seven cooling plants and six accumulators in the ATLAS service cavern. From these two central locations, a network of coaxial transfer lines stretching several kilometres, along with multiple layers of manifolds, will distribute CO2 to thousands of evaporator pipes that cool the ATLAS and CMS detectors in the experimental caverns.

Installation of the first accumulator in the service cavern of ATLAS. (Photo by Martin Doubek)

In both experiments, the underground cooling equipment will be linked to a R744 (CO2) based primary cooling system that sits on the surface. These primary systems were designed by CERN’s EP-DT and EN-CV groups in collaboration with the Norwegian University of Science and Technology and subsequently developed industrially by EN-CV. The primary systems incorporate an advanced adaptation of a transcritical CO2 cooling process, capable of delivering stable cooling down to -53°C while efficiently transferring heat to the experiment’s surface.

The installation of the 2PACL cooling plants and associated equipment will continue through 2025 in CMS and during LS3 in ATLAS, followed by an extensive commissioning phase to fine-tune the new systems. The several kilometre-long distribution pipework installation, already started in both experiments in 2025, will continue during the next Year-end Technical Stop (25/26) and during Long Shutdown 3, ensuring readiness for the HL-LHC era.

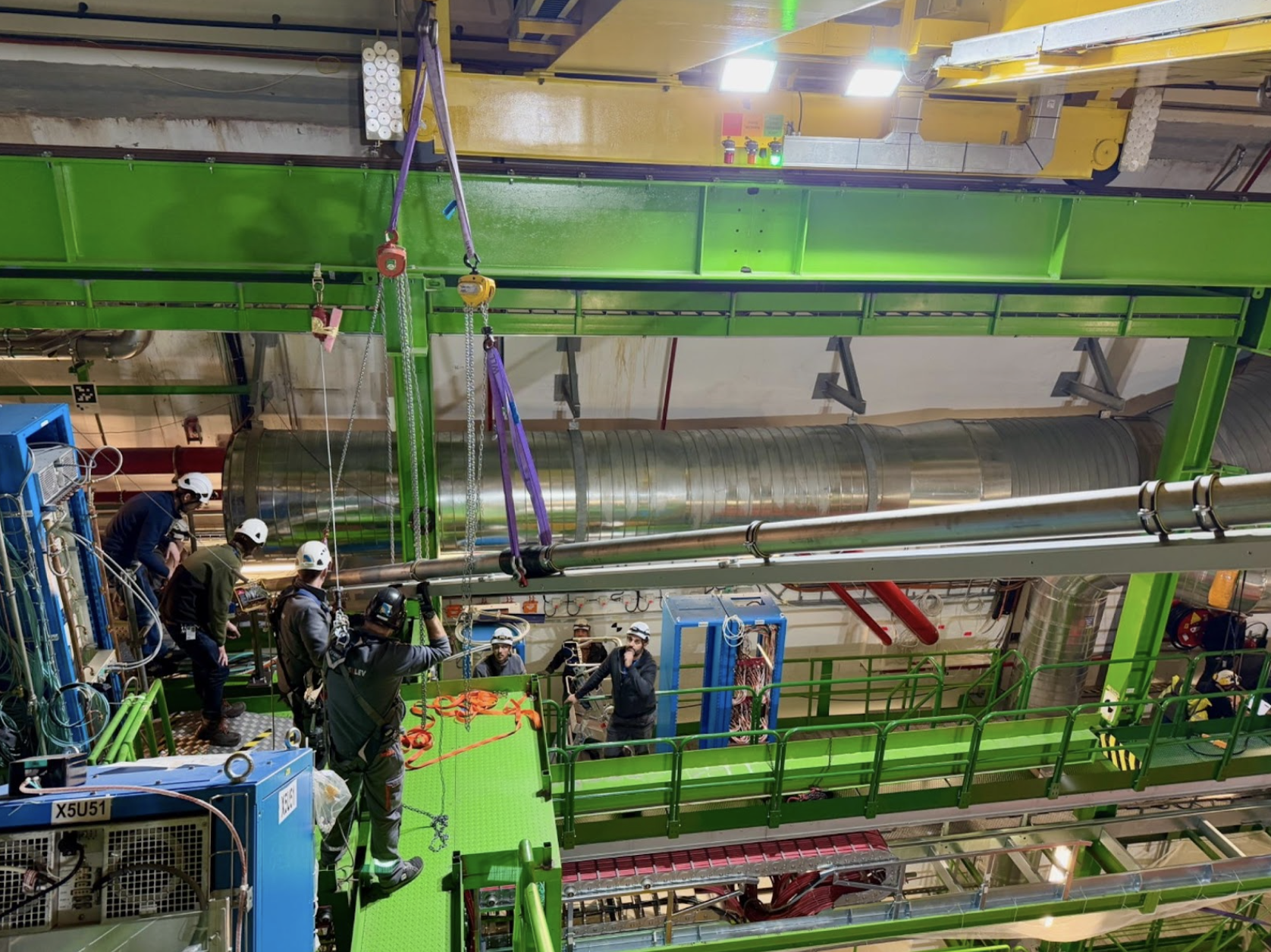

Insertion of an 11 m-long transfer line section between the experimental and service caverns of CMS. (Photo by Jérôme Daguin)

Due to the substantial volume of CO2 required for operating such large systems, a 12-cubic-meter storage vessel will be installed on the surface at the experiment's surface sites in ATLAS and CMS. Managing fluid exchanges between this storage unit and the underground cooling infrastructure necessitated innovations in industrial control systems. Since only a limited number of components from previous CO2 cooling systems could be scaled to meet the new demands, the development effort also involved identifying and qualifying a broad range of new suppliers for this advanced cooling technology.

CO2 cooling system’s control cubicles in the Service Cavern of CMS. (Photo by Jérôme Daguin)

New CO2 control systems for both ATLAS and CMS will extend from the surface down to the underground facilities. Redundant master Programmable Logic Controllers (PLCs) will be installed on the surface, interconnected with distributed input/output modules and slave PLCs located in the underground service caverns via fiber optics. A state-of-the-art double-star redundant architecture is being deployed to ensure the highest level of system reliability—critical for keeping the silicon detectors consistently cold.

A total of 21 programmable logic controllers (PLCs) and 106 control and power distribution cubicles will be installed across both the ATLAS and CMS experiments. As of today, 13 PLCs have been installed in CMS and 6 in ATLAS. All 60 cabinets planned for CMS have already been installed and are currently being cabled. In ATLAS, 21 of the planned 46 cabinets have been installed so far. The remaining installations will take place during LS3, once space becomes available following the decommissioning of the current system.

The implementation of these advanced CO2 cooling systems marks a critical milestone in preparing the ATLAS and CMS experiments for the challenges of the High-Luminosity LHC era. With unprecedented cooling demands, the success of this project relies not only on innovative thermal engineering but also on the seamless integration of large-scale infrastructure, industrial automation, and control technologies. The use of CERN’s UNICOS framework and the WinCC OA SCADA system ensures that the new installations will meet the highest standards of reliability, safety, and performance. As installation progresses and commissioning begins, these systems stand as a testament to the collaborative effort and technical ingenuity driving the future of particle physics.

Acknowledgment: The authors would like to thank the EP-DT-FS, ATLAS, and CMS cooling teams for their contributions and support.