A portable gas system for particle detectors.

Today, about 30 gas systems are used to deliver the right gas mixture to the corresponding gaseous detectors at the LHC experiments. The detector gas mixture is the sensitive medium where the charge multiplication produces the signal that is then recorded and analysed. The correct and stable gas mixture composition is therefore the key ingredient for an efficient and reliable operation of the LHC experiments.

Gas systems of the LHC experiments are the result of a strong collaborative effort between CERN’s Gas Systems Team (nowadays part of CERN/EP-DT-FS) that designed and build the gas systems and the CERN/BE and CERN/EN departments that develop software controls and provide the primary gas supply, respectively. The operational experience over the last years has demonstrated an impressive reliability level: greater than 99.95% corresponding to less than 1.5 hours of down-time per year (power-cuts and external problem excluded).

The reduction of any emissions and operational costs can be achieved by recirculating the gas mixtures used in the detectors. Especially the control of greenhouse gas (GHG) emission is an important subject for the operation of the current experiments but also for the design of future particle detectors as new regulations will put more stringent limits while may also result at higher costs.

Nowadays R&D activities with gaseous detectors are ramping up as part of the LHC detector upgrade programs, as for example long-term detector tests, detector quality assurance before installation in the experiments, test-beam and laboratories tests. To minimise the emissions coming from these activities, the EP-DT Gas Systems team has developed a compact and flexible gas recirculation unit, which is about ten times less expensive than a standard LHC gas recirculation system. The main features of this gas recirculation unit are its flexibility and its user-friendly operation: it can be easily adapted for all types of gases and detectors as well as for specific requirements (recirculation fraction, low/high flow rates, detector working pressure, gas cleaning agents, etc.).

To address different user requirements, the unit follows a modular design and is divided in several logic modules. Two recirculation units are operational since more than two years for two different set-ups: CMS Cathode Strip Chamber test at GIF++ and gas recirculation development for Gas Electron Multiplier.. The first few years of operation have confirmed an extremely high reliability and stability of the two recirculation systems, which work in different conditions (recirculation flow, pressure, etc.) and with different detector types. Based on the development of this recirculation unit, the CERN Gas Systems team developed also the gas recirculation plant for the LHCb GEM detector, which is running stable since 2016 and allowed a 90% reduction of the CF4 consumption.

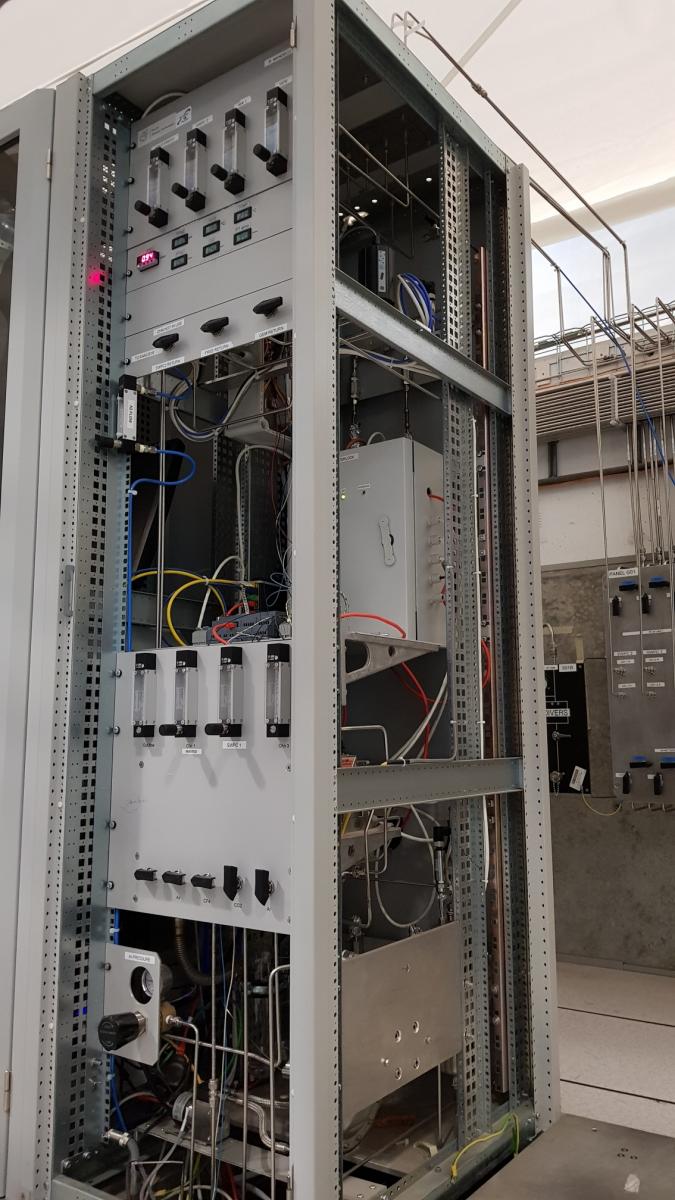

Figure 1: Front and rear view of the gas recirculation unit. The different logic modules are highlighted.

The principle of operation of this portable unit is based on a pump ensuring the gas circulation and extraction from the detector. Through several settings the users can choose the gas recirculation rate as well as the detector pressure, the gas flows ensuring the right mixture for the detector. A gas analysis module is installed after the distribution module allowing to analyse the gas exiting the detectors or coming from the purifier module. Though it allows to use different types of gas analysers the primary choice has been the use of H2O and O2.

Finally, monitoring is based on several electronic and software tools. Since one of the goal of the development of the new gas recirculation unit was the cost-effectiveness, it was decided to not have any remote control though a higher-level of automation is possible by upgrading the user interface.

The choice of instruments and materials has been done considering the experience of the LHC gas systems, the quality-price relation and the availability on the market. This year a new unit has been installed at the Gamma Irradiation Facility for the ATLAS and CMS Resistive Plate Chamber (RPC) R&D and it will allow a significant reduction of GHG emissions coming from the use of C2H2F4 and SF6. More units are currently under construction for different detectors technologies that will be tested on a long-term basis in laboratories, beam-tests or irradiation facilities.

The author would like to thank Beatrice Mandelli and Roberto Guida (EP-DT) for the invaluable contributions and comments.

You can read the full paper published in Jinst (IOP): here.