DT group publishes annual report

The mandate of the Detector Technologies (DT) group in the Experimental Physics department covers development, construction, operation and maintenance of particle detectors for the experiments at CERN. Recently, the group published its 2019 annual report reporting the progress on several detector projects for LHC and non-LHC experiments, the operating services open to all CERN users for detector operation and last but not least its active participation in R&D projects for the development of new technologies and infrastructures.

Several years ago, specific partnerships for Phase I detector upgrades were launched with CERN teams in ALICE and LHCb; they are all progressing well. Moreover, detector prototyping support for the ATLAS and CMS detectors for the Phase II upgrade is going on in parallel. The group optimized the support to the experiments in the phase 2019-2027, where demanding detector R&D and prototyping for LHC Phase II upgrade projects overlaps with the finalization of the construction and installation of Phase I upgrade projects and the preparation of new experiments and studies. In addition, DT continued through 2019 to provide technical support to CERN’s Small and Medium Experiments, such as NA62 and CLOUD while continuing contributing to DAQ and DCS for the CERN Neutrino Platform activities. Finally, group members are actively engaged in detector studies for possible future lepton colliders, the DUNE experiment and the Search for Hidden Particles (SHiP).

The DT group is actively involved in the EP Department’s 5-year R&D programme; promoting current efforts on detector R&D and driving a culture of innovation of novel technologies and related infrastructures. Several members of the group are strongly involved in the R&D programme, in particular in the areas of Silicon Detectors, Gas based Detectors and Detector mechanics and cooling.

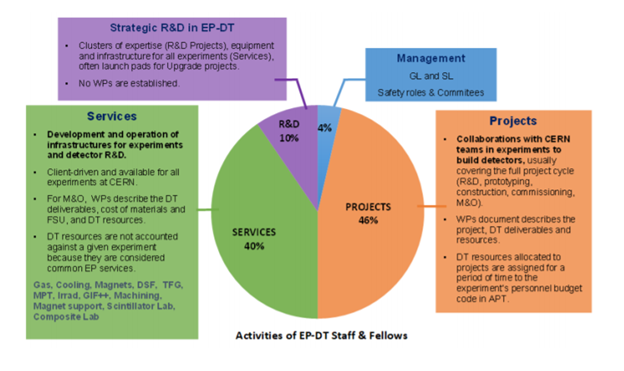

The recently published report reviews projects falling in the three main categories of the group’s expertise. According to it, in 2019 about 46% of the Members of Personnel (Staff and Fellows) were allocated to projects; about 40% of the group provided service activities and 10% carried out predominantly R&D related work, including leadership of R&D collaborations and EU co-funded projects. Finally, the remaining 4% of the group’s resources were devoted to safety tasks, participated to CERN-wide committees and the management of the group.

2019 has been the year in which most of the ALICE experiment have been removed to undergo a major upgrade. One after the other the beam pipe, the central tracking detectors and the giant TPC have been extracted and moved to the surface. A new beam pipe with a smaller diameter, a new Inner Tracking System (ITS), and a new vertex tracker for forward muons (MFT), will replace the old central detectors while the large Time Projection Chamber (TPC) has been completely renewed with new GEM detection chambers. For the new TPC, the production of large-size GEM foils at the EP-DT Micro-pattern Technologies workshop has been completed with GDD Lab support for the GEM foil test. The final assembled TPC chambers have relied on the support of GIF++ Lab for the full characterization. One year of intense activity in the P2 clean room, under TPC team leadership, has been extensively supported by the DT engineering team in all the different phases. From the old chambers dismounting to the new GEM chambers installation, the EP-DT team has contributed in the preparation of all the specific infrastructures, the development of mechanical solutions and the delicate interventions inside the TPC for the interface reconfiguration.

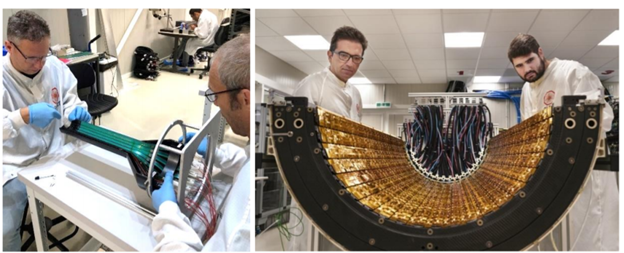

In 2019 the new ALICE ITS has taken its final shape, in a dedicated cleanroom in building 167 of the Meyrin site, where now it is being tested and prepared for the final phase of installation and commissioning. A selection of 192 staves, built at CERN and in five construction sites in Europe and in the United States, have been integrated in the 167 clean room, by the ALICE DT team, to form the Inner (3 layers) and Outer (4 layers) Barrels for a total area of 10m2 and 12.5 billion pixels. While the Detector is being pre-commissioned, the subsequent ITS installation phases in ALICE are being prepared through several detailed verifications and through the finalization of all the required hardware. This includes the Cage, a large carbon composite structure, that provides support and positioning inside the TPC to the ITS, MFT and beam pipe, produced under DT responsibility.

Figure 1: ALICE ITS Inner Half-Barrel (3 Half-Layers) and Outer Barrel (4-Half Layers) during construction.

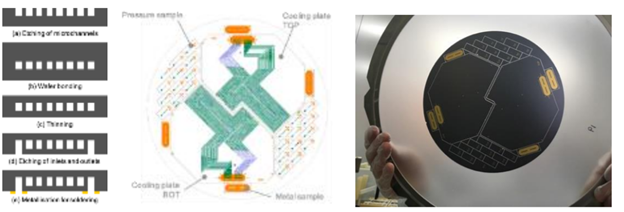

During 2019 several sub-detectors of the original LHCb experiment have been removed to make space for the upgraded detector. It will be able to read out all sub-detectors at 40MHz and to select physics events of interest by means of a pure software trigger. This capability will allow the experiment to collect data with high efficiency at a luminosity of 2 × 1033 /cm2 /s. In 2019, DT continued to provide engineering support for the cooling, mechanics and integration. The group supported the LHCb collaboration during the microfabrication process of the cooling. All the cooling plates have been delivered in three batches during the course of 2019 allowing the VELO team to continue working on the assembly with minimum impact on the production schedule.

EP-DT played a key role in the development of the microfabrication process that led to the production of state-of-the-art large silicon cooling plates with embedded micro-channels for the circulation of bi-phase CO2. These plates, just half a millimeter thick, will be used to cool the hybrid pixel sensors of the new VELO to be installed in LHCb during LS2. A complex multistep microfabrication process was implemented at CEA-Leti by the Leti-3S team on 8-inch silicon wafers featuring two micro-channel cooling plates and smaller test structures. These cooling plates are also the mechanical backbone of the VELO modules which will come as close as 5 mm to the proton beams and therefore will allow LHCb to localise precisely the points at which beauty and charm particles decay.

Figure 2: Left: Simplified microfabrication process-flow of the VELO cooling plates. Centre: Layout of all the photolithography layers. Right: 200mm silicon wafer bonded stack with 2 cooling plates, 4 soldering samples and 18 pressure samples.

The group also contributed to the integration of services for the installation and operation of the SciFi tracker, the replacement of the Outer Tracker (based on gas straw tubes) and Inner Tracker (Silicon microstrips) by a single detector technology and will be installed in LS2. The EP-DT gas system team has built a gas distribution system in the LHCb cavern to supply dry gas to all the cold-boxes housing the SiPMs, which allow operation the SiPMs down to -40°C without condensation problems. To monitor the gas flow in the coldboxes, the EP-DT Detector Interface (DI) section has built a readout system for 48 flowmeters to allow commissioning of full C-frame in the surface assembly hall including the controls software. The system was designed to be scalable to the full cavern system. EP-DT spearheaded a campaign to find a solution to a condensation problem on various SciFi detector components. EP-DT members and has been implemented all C-frames. To improve monitoring of potential condensation, ~500 PT100 temperature sensors was added to the design of the SciFI C-frames.

Figure 3: Assembly and testing of 4 LHCb SciFi C-frames in parallel at the surface at P8.

The group also contributes to the Phase II Upgrade for the ATLAS experiment. As part of the Phase II Upgrade for the ATLAS experiment, an all-silicon tracker capable of coping with the demands of the High Luminosity Large Hadron Collider (HL-LHC) will replace the current Inner Detector and this is one of the projects where EP-DT has invested significant resources. The so-called Inner Tracker (ITk) will comprise a Strip Tracker and a five-layer Pixel detector. In 2019, the DT group continued playing an important role in the development of the latter. Once again the DT efforts focused on the Outer Barrel (OB), working closely with EP-ADE on the design, prototyping and coordination aspects of the project. The Outer Barrel region of the future ATLAS Pixel detector comprises three sensing layers (i.e. layers 2 to 4) at different radii, each featuring three sections: a central flat part where the pixel modules are parallel to the beam pipe; and two tilted regions, one at either side, where the normal of the active elements forms an angle between 55° and 67° with respect to the beam axis. The design of the OB global structures continued in 2019, focusing on the so-called half-layer shells. Each OB layer comprises four of these semi-cylindrical carbon structures, which support the inclined half rings and are joined by the corresponding longerons. Special attention was paid to develop the shell features used to position and fix the local supports and the interlinks connecting the three OB layers together.

In parallel to the design and analysis work, the prototyping activities for the Pixel Outer Barrel continued during the past twelve months. As part of this effort, full-size prototypes of the carbon structures to be used in the functional local supports were produced at the EP-DT composites lab, including the very first inclined half-rings (see figure below). The team also delivered the first batches of titanium evaporators and manufactured the required test specimens to qualify the radiation hardness of the various adhesives, resins and thermal interface material employed in the design. In 2020, these components will be used to assemble prototypes of the functional longerons and inclined half-rings, which will be tested as part of the qualification strategy.

Figure 4: Full-size prototypes of the carbon composite structures to be used in the functional longeron and inclined half-rings of the Outer Barrel.

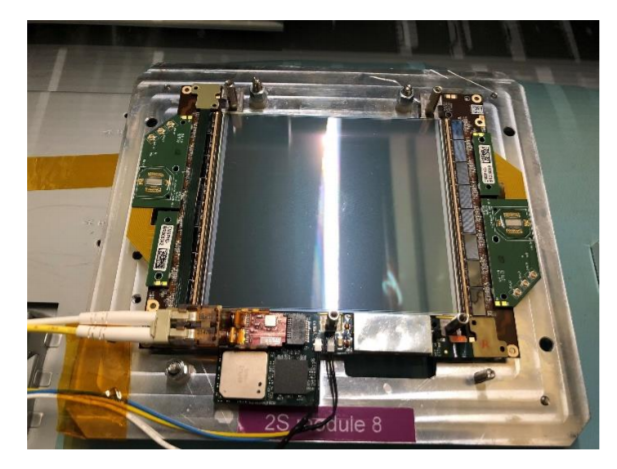

For the CMS Tracker’s Phase 2 upgrade, scheduled for installation during LHC LS3, the EP-DT group collaborates with the CMS team in the development and construction of the Outer Tracker, as well as Tracker’s common items and integration. DT has a central role in the development of the 2S (two strip sensors) and PS (pixel and strip sensors) modules for the Outer Tracker. The focus of DT’s contribution is on the development of the assembly techniques and qualification process for these novel module types, preparing and maintaining 3D models and 2D drawings of the modules’ mechanical assemblies, and performing mechanical and visual QC of the module hybrids prototype. Further full size 2S module prototypes were built in 2019. The most recent module built is equipped with FE 8CBCv3.1, a prototype service hybrid and optical readout prototypes (see following figure). The aim of the module assembly is to test and refine the module design details and assembly procedures, as well as to evaluate the mechanical functionality of the module components. In addition, in 2019, about 100 Front-End hybrids were visually inspected and detailed reports were prepared to be used for reviewing the assembly processes with the vendors.

Figure 5: The latest CMS Outer Tracker 2S module built at the CERN DSF cleanroom. This module is already close to the final module design needed for CMS. Several electronics and optical components are here still with development versions, while waiting for the final fully integrated and miniaturized versions to be available.

The CMS experiment will upgrade its calorimeter endcaps for the HL-LHC phase with a high granularity sandwich calorimeter, the CMS Calorimeter Endcap (CE), also referred to as the High Granularity Calorimeter (HGCAL). It will have an active area of 600 m2 of silicon sensors with 6 million individual readout cells and 500 m2 of scintillator tiles coupled to Silicon Photomultipliers with half a million readout cells. In 2019, group members focused on the electrical characterization of HGCAL silicon sensors and on the commissioning of novel silicon-sensor testing systems for the radiation-hardness qualification of the HGCAL silicon sensors. Furthermore, the team actively contributed to ongoing analyses of data from the 2018 beam tests of HGCAL prototypes at CERN and DESY, Hamburg.

For the ongoing radiation-hardness qualification of HGCAL silicon sensors, several groups of the EP department purchased together a probe station shown in the picture above, which was delivered, installed and commissioned at CERN in 2019. The highly customized, semi-automatic and temperature-controlled probe station covers a temperature range from -40°C to 200°C. The ability to keep the sensors cold during testing is crucial for avoiding uncontrolled isothermal annealing of the irradiated silicon sensors during the testing.

Figure 6: A semi-automatic temperature-controlled probe station used for HGCAL silicon sensor radiation hardness qualification.

Two main elements marked in 2019 the progress on the first prototype of the future large CO2 cooling systems for ATLAS and CMS (DEMO project). The first one was the delivery at CERN of the first LDG3 CO2 pump by the industrial partner LEWA. This pump, although belonging to an existing class of LEWA pumps, is a first of its kind for pumping CO2 at very cold temperatures. For this reason, a dedicated pump test-bench has been designed and produced by EP-DT. Since its reception the pump has been set in continuous operation at maximum stroke and maximum frequency under constant monitoring. More than 5,000 hours of functioning have been monitored, providing very comforting results about the reliability of the device and useful information for the next units to be produced. The test-bench has been designed to be transportable: it will be sent to LEWA before the production of all future pumps and will always travel with them, used for both acceptance and endurance test of each unit prior to their implementation in the plant. The second marking event has been the launch in production of the first prototype of R744 (conventional name of CO2 when used in refrigeration systems) primary chiller. The design of this unit, based on an innovative trans-critical cycle, has been developed by DT in collaboration with EN-CV and the Norwegian University of Technology (NTNU).

Figure 7: The new EP-DT test bench for the large pumps of the DEMO and future detector cooling systems.

With this project, partially funded by the CERN Environmental Protection Steering board (CEPS) the CERN experiments mark their entrance in the field of green refrigeration, contributing to the reduction of the laboratory’s environmental footprint. The procurement and future operation of all the units following this first prototype will be assured by EN-CV, partner of EP-DT in this development. In addition to the activities related to the DEMO project, 2019 has been a very dense year for the design and integration of the ATLAS cooling related activities and the CMS CO2 cooling systems design and integration.

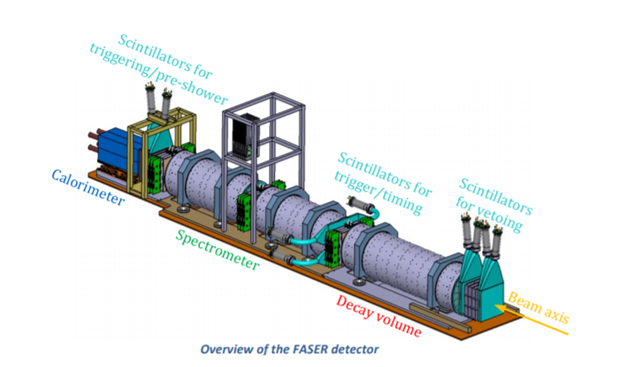

This is only a small list of the different projects in which the DT group is involved offering innovative solutions and providing the needed infrastructure for testing and developing new detectors. It should also be noted the DT’s significant contributions to the recently approved FASER experiment. The vetoing and triggering system is based on plastic scintillators. Those have been designed and produced in the EP-DT Scintillator Workshop. Since FASER will see a huge background of high energy muons, it is extremely important that the vetoing system is very efficient. Therefore, it has been designed to be based on 4 layers of plastic scintillators each with a thickness of 2 cm. Since the overall length of FASER is limited by the location, it is very important to limit the space requirements of each system. To limit the space needed for the scintillator pairs, the light guide has been made with an angle that allow the scintillators to be installed directly back to back as shown in the figure above.

it has been designed to be based on 4 layers of plastic scintillators each with a thickness of 2 cm. Since the overall length of FASER is limited by the location, it is very important to limit the space requirements of each system. To limit the space needed for the scintillator pairs, the light guide has been made with an angle that allow the scintillators to be installed directly back to back as shown in the figure above.

Last but not least, the DT group contributed to the non-LHC experiments and the report details work for NA62, for CLOUD, AMD and ISOLDE for which the DT group members provided valuable support during 2019.

Finally, EP-DT has largely contributed to the engineering studies for the DUNE cryostats, as well as the Data AcQuisition (DAQ) and Slow Control (SC) systems of the far detector. Two far detector prototypes (ProtoDUNE: NP02, NP04) have been built at CERN, within the Neutrino Platform project and thanks to the collaborative work we already have the first results to analyse and understand the potential and limits of these technologies.

Read the 2019 annual DT report and find out more about the work of the group: HERE