Calorimetry and light-based detectors for future experiments

The strategic R&D programme on technologies for future experiments by the CERN EP department is currently in its second phase from 2024 until 2028. Within this effort, Work Package (WP) 3 focusses on the development of calorimetry and light-based detectors.

Particle identification

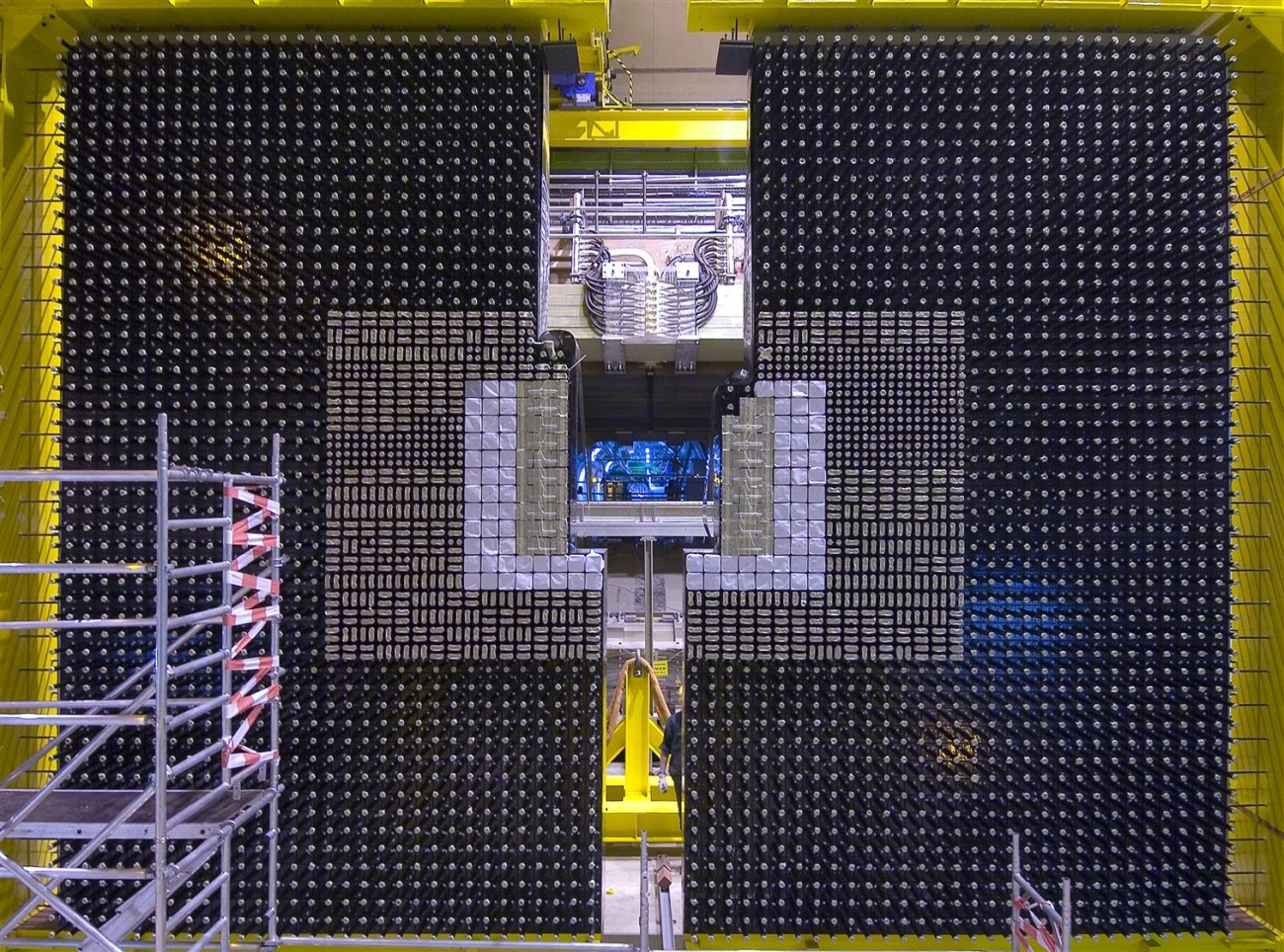

Several detectors use light to detect particles, but Ring-Imaging Cherenkov (RICH) detectors go a step further: they measure the angle at which Cherenkov light is emitted to determine the particle's velocity. Combined with the particle’s momentum, this allows for the calculation of its mass, enabling precise identification of the particle type. To do that, a “radiator”, an optical system and an imaging camera are needed. The radiator is usually a gas, the optical system an array of mirrors and the camera an array of single-photon sensitive sensors, which will provide space and time coordinate of each emitted photon. All these components are studied and further developed in the EP R&D programme, in order to be ready for future challenges including higher radiation levels and event rates, better precision in the particle identification and an enormous amount of data to be processed. This includes improved SiPM array photon detection efficiencies (Fig. 1) and durability in cryogenic environments, lighter construction and special composite precision optics, suitable green gases as radiators. Last but not least, advanced optoelectronic chains to space and timestamp each detected photon and transfer it to the computing farm for further processing.

At present, the main effort is on - the cryogenic set-up hosting SiPM Arrays with special flex cables, which will be used in beam tests; - the newly CERN-developed FastRICH chip, which will provide each photon with precise (~25 ps) time information and - special coatings and flat lightweight mirrors for the detector components (Fig. 1). WP 3 has strong collaboration with the LHCb RICH team and plans to apply some of today’s R&D on the future upgrades of those detectors.

Figure 1: Prototype modules for single-photon detection at next-generation RICH detectors being tested for picosecond timestamping at the SPS facility [1] (left). Example of RICH optical mirror system at LHCb (right).

Scintillator-based calorimetry

Several R&D activities within WP 3 focus on the use of scintillation light for calorimetry. Scintillator-based sampling technologies are being developed for both electromagnetic (SpaCal) and hadronic (TileCal) calorimeters. In parallel, research is also being conducted on the development and optimisation of new scintillating materials. Spaghetti Calorimeter (SpaCal) technology consists of scintillating fibres inserted in a dense absorber, lead or tungsten. Time resolutions better than 20 picoseconds have been achieved using organic and inorganic scintillating fibres with high-energy electron beams. SpaCal technology can be adapted to meet the requirements of LHCb Upgrade II, Higgs factories, FCC-hh and fixed-target experiments at the intensity frontier.

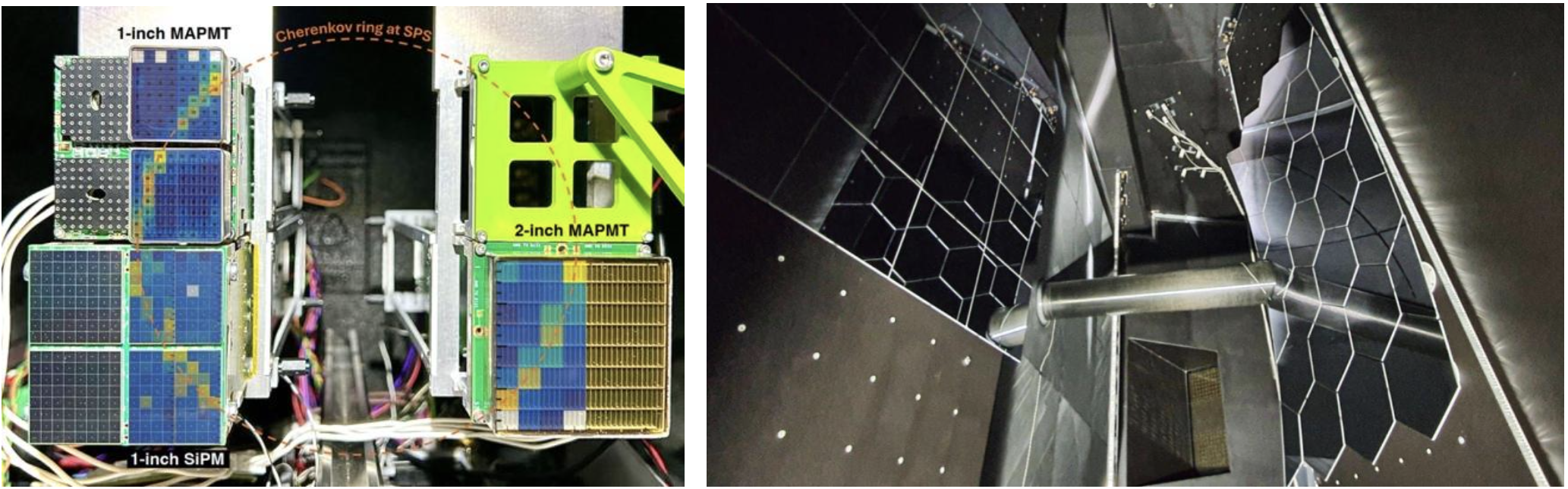

A SpaCal absorber block made of lead is currently being produced in a novel approach within WP 3. In contains 3136 steel capillary tubes that are held in place by copper matrices in the casting mould (Fig. 2). The steel capillary tubes are ideal for the insertion of radiation-tolerant organic scintillating fibres.

Another important activity is the optimisation of radiation-hard hollow light guides for SpaCal calorimeters. The spatial homogeneity of various geometries has been compared in a test bench that was assembled at CERN (Fig. 2). In recent beam tests at the SPS, it was found that the optimised light guides allow achieving a constant term of the energy resolution with about 1% precision.

In the coming years, the overall SpaCal module design and optimisation effort will continue. A feasibility study for the usage of SiPMs in view of detector concepts with space constraints is starting, complementing studies on photon detectors with excellent radiation hardness.

Figure 2: Test bench assembled at CERN for the optimisation of hollow light guides (left). Casting mould for SpaCal lead absorbers (right). The steel tubes that will house the scintillating fibres are held in place by copper matrices.

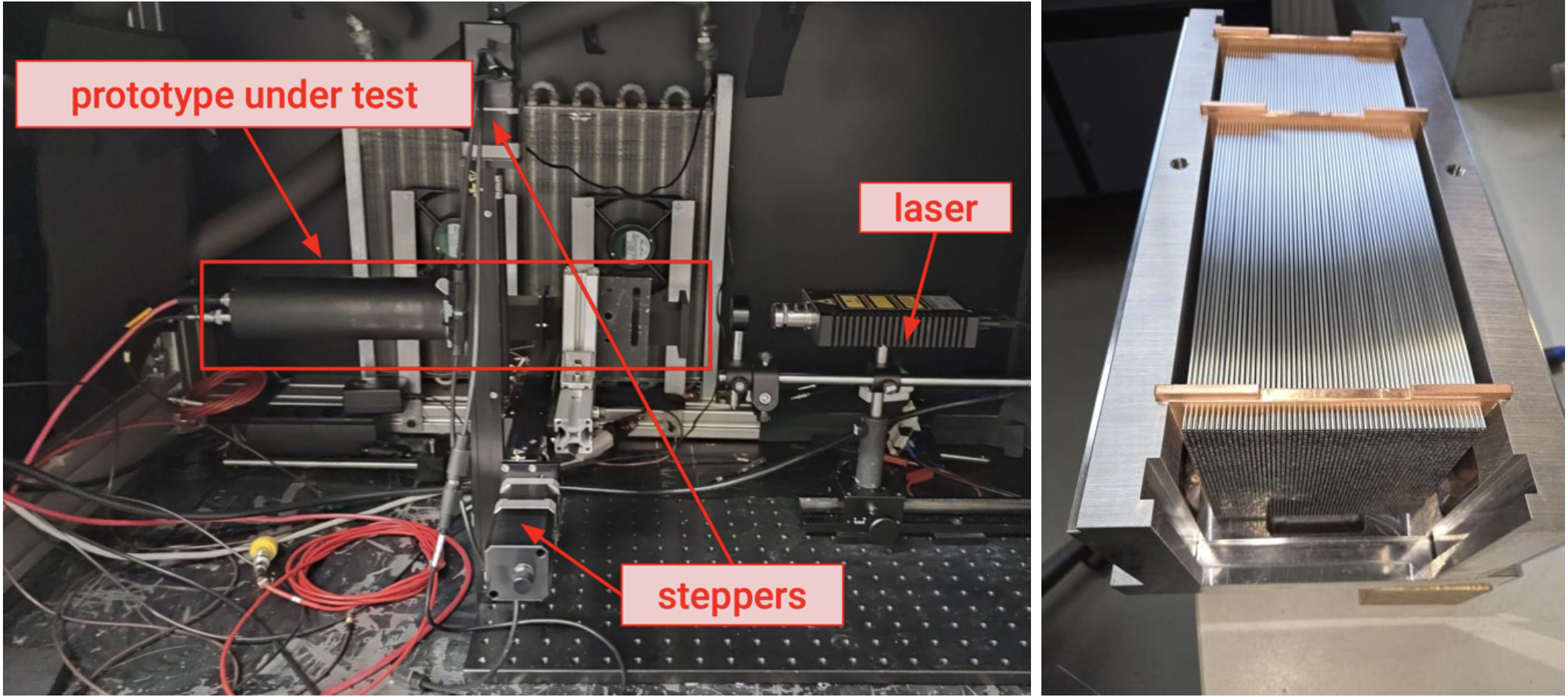

The R&D on scintillating materials, performed in close collaboration with the crystal clear collaboration, covers all aspects of light-based detectors. Various light production methods in inorganic crystals were studied, with a focus on picosecond timing. The investigated materials included intrinsic, doped, and cross-luminescent scintillators, as well as Cherenkov radiators, and novel materials based on nanocrystals. Several of the studied materials demonstrate excellent time resolutions at 511keV of 60 to 100 picoseconds, and with minimum ionising particles of below 20 picoseconds (Fig. 3). Ray-tracing Monte Carlo simulations were instrumental in understanding the underlying mechanisms defining the time resolution of detectors.

Among the considered materials, an extensive study has been performed on cerium-doped garnet crystals in close collaboration with producers. While bright and radiation-hard at the level of 1 MGy, the cerium lifetime leads to effective decay times of tens of nanoseconds. Adding divalent ions like Mg or Ca accelerates the emission to a few nanoseconds (Fig. 3). Tunability and radiation hardness make garnets outstanding candidates for a wide range of applications.

R&D on organic scintillators was also initiated, aiming at radiation-tolerant compositions with better timing than the largely used 3-Hydroxyflavone (3HF) plastic scintillator. The explored options include polysiloxane or organic glass hosts, green/red-emitting dyes, and nanocomposites.

Figure 3: Comparison between measured and simulated (with 1-standard-deviation green band) time resolution of the tested crystals under 150 GeV 𝜋+ beam [2] (left). Scintillation decay under pulsed X-rays excitation in GAGG samples with increasing Ce, Mg concentration (PL1–PL6) [3] (right).

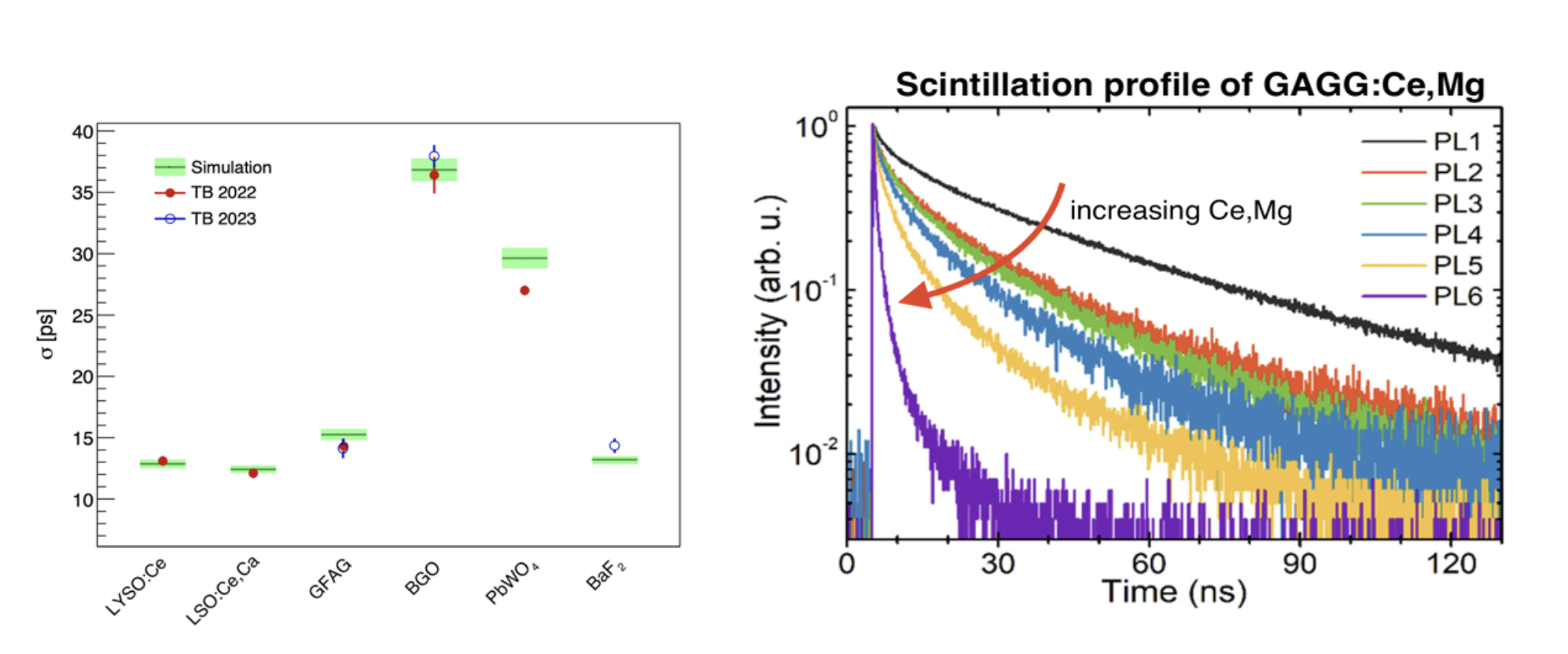

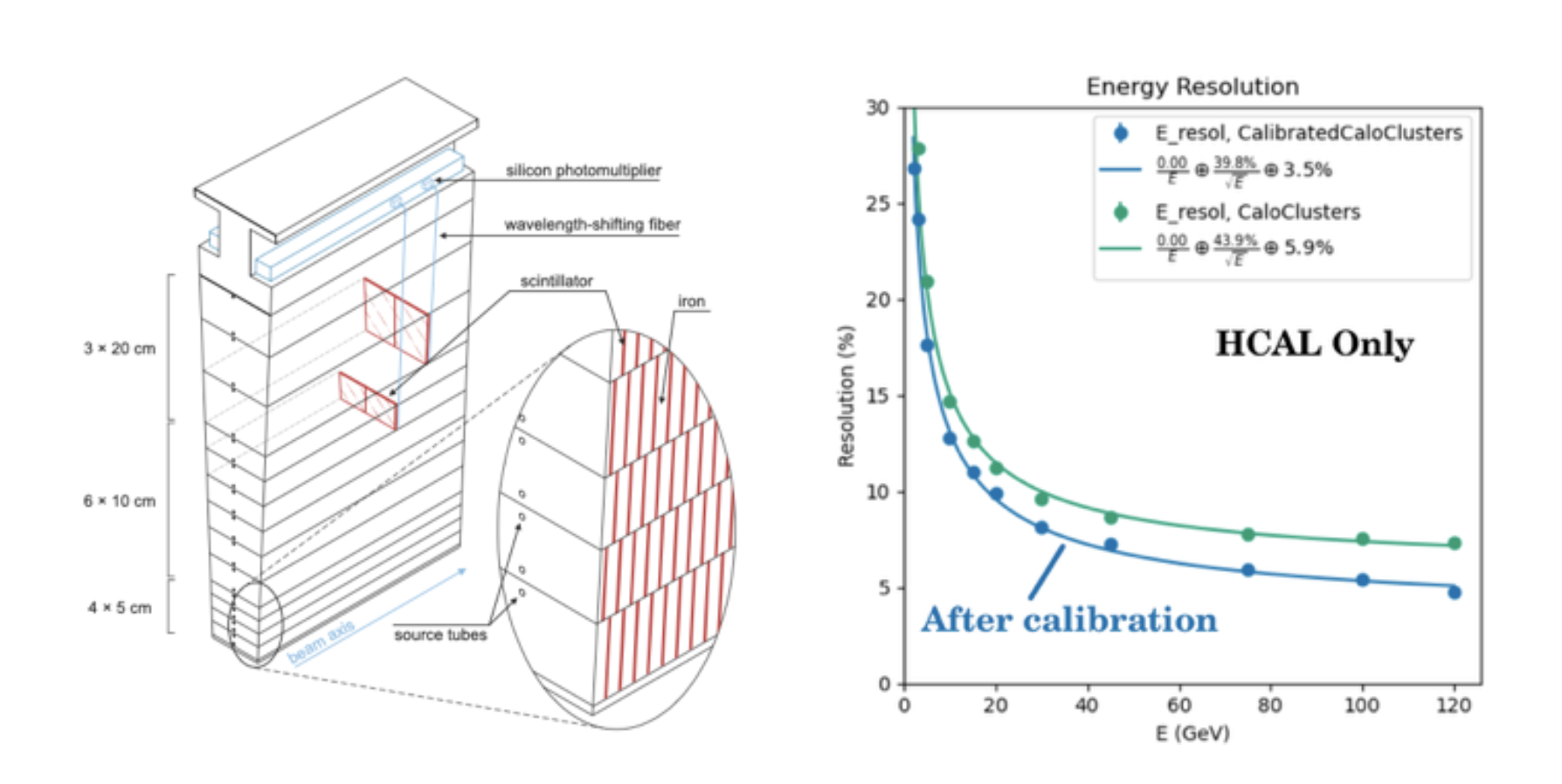

An important trend in calorimetry is the move toward significantly increased granularity in the design of next-generation detectors, enabling the application of particle flow-based energy reconstruction techniques. An activity with WP 3 studies the performance and optimisation of a hadronic calorimeter, inspired by the layout of the ATLAS Tile Calorimeter, but with an order of magnitude higher granularity (Fig. 4).

A prototype setup will be produced for future beam tests. The increased granularity will be achieved by reading every scintillating tile with an SiPM. This design is being adapted to the requirements of the ALLEGRO detector proposed for FCC-ee. The advantages of the design, aside from the increased granularity, are the possibility of in-situ calibration with a radioactive source, keeping the electronics out of the active volume, easing access for services such as power and cooling, and for maintenance.

Figure 4: TileCal technology adapted for FCC-ee (left). Energy resolution obtained for such a calorimeter in simulations (right).

Noble liquid calorimetry

R&D on Noble Liquid Calorimetry at CERN is carried out within the ALLEGRO framework, a detector concept for FCC-ee centered on a Noble Liquid Ionization Electromagnetic Calorimeter. Designed for high granularity and Particle Flow compatibility, it uses inclined PCBs interleaved with absorbers and spacers to define uniform gaps for the active liquid medium. CERN has led key aspects, including PCB development, geometry optimisation, and mechanical design.

The calorimeter features 11 layers with 2 × 1.8 cm² cells, and a finer segmented strip layer in the second layer envisioned to enhance photon/pion separation. Simulation studies show that electromagnetic showers develop deeper due to limited upstream material, and repositioning the strip layer can improve the separation. Shower shape variables are analysed, and advanced methods like BDTs and CNNs are under consideration to improve separation performance at higher energies.

A new PCB prototype has been designed and produced. Laboratory characterization and full-scale electromagnetic simulations show that design updates significantly reduce cross talk. Initial signal injection tests confirm the simulation results.

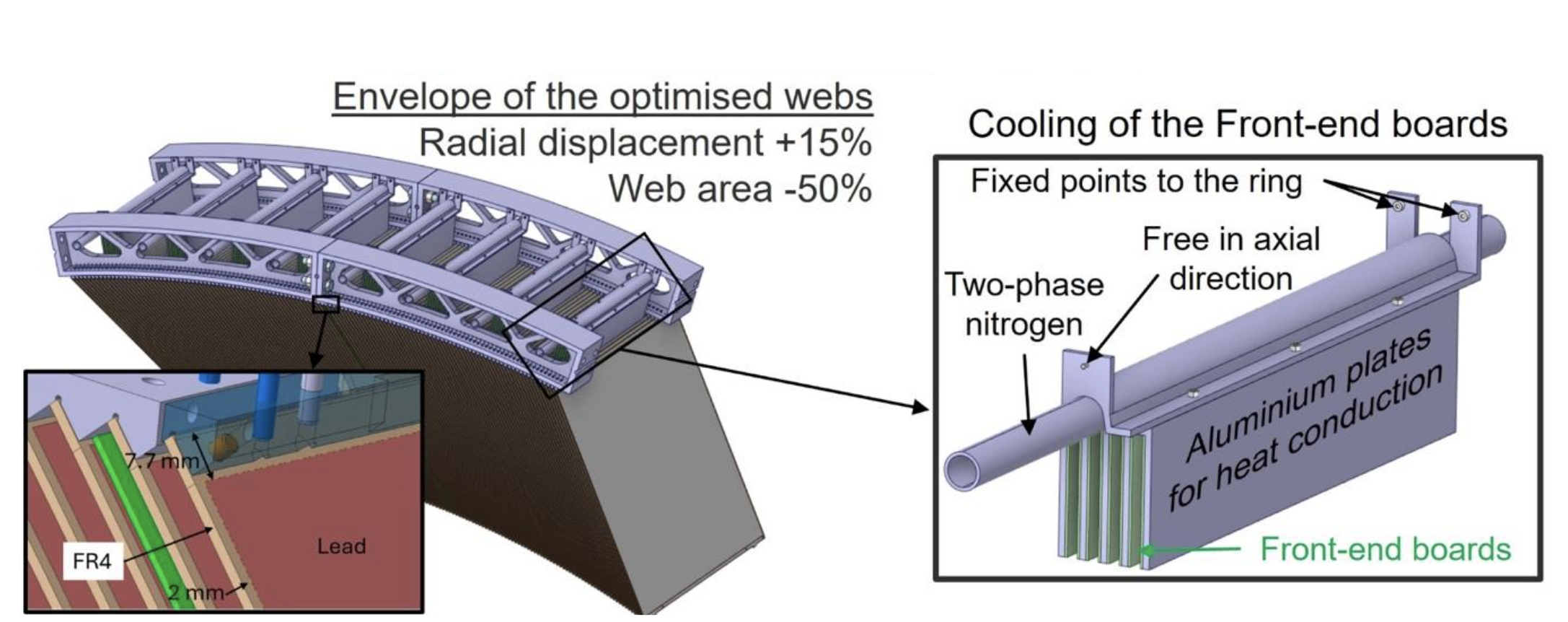

On the mechanical side, support rings were re-engineered to reduce the web area by 50%, increasing radial deformation by only 15% (see Fig. 5). This modification creates space for readout cables and two-phase nitrogen cooling pipes to extract heat from the front-end electronics and prevent argon boiling.

Figure 5: Optimised mechanical design of the support rings.

Summary

Calorimetry and light-based detectors play an essential role in present and future particle detectors. The strategic R&D ongoing in WP 3 focusses on a set of novel technologies, materials, and techniques to reach better resolutions in space and time, preparing the particle detectors for the challenging environments of next-generation experiments.

References:

[1] M. Bartolini et al 2025 JINST 20 P03034

[2] R. Cala' et al 2025 JINST 20 P04004

[3] L. Martinazzoli et al., Mater. Adv., 2022,3, 6842-6852