ATLAS NSW Upgrade: preparing installation and commission of its first sector

The New Small Wheel (NSW) Upgrade it the most complex and challenging Phase-1 Upgrade project of ATLAS. As all the other upgrade projects for the LHC experiments, the goal is to meet the challenges of the High-Luminosity LHC era and to cope with the unprecedented levels of pile up and background rates.

As discussed in a previous EP Newsletter (A New Small Wheel for ATLAS is taking Shape, December 2018), the two New Small Wheels will replace the innermost stations of the ATLAS Endcap Muon Spectrometer. While the basic geometry is the same for the two detectors (each consisting of 16 pie-shaped sectors), pretty much nothing else will remain the same: Monitored Drift Tube (MDT), Cathode Strip (CSC) and Thin Gap (TGC) Chambers will be replaced by the novel Micromegas (Micro-mesh gaseous structures) detector technology, in combination with small strip Thin Gap chambers (sTGC). Moreover,the number of detection planes will increase from 4 (in the present CSC region) or 8 (in the MDTs) to 16.

As discussed in a previous EP Newsletter (A New Small Wheel for ATLAS is taking Shape, December 2018), the two New Small Wheels will replace the innermost stations of the ATLAS Endcap Muon Spectrometer. While the basic geometry is the same for the two detectors (each consisting of 16 pie-shaped sectors), pretty much nothing else will remain the same: Monitored Drift Tube (MDT), Cathode Strip (CSC) and Thin Gap (TGC) Chambers will be replaced by the novel Micromegas (Micro-mesh gaseous structures) detector technology, in combination with small strip Thin Gap chambers (sTGC). Moreover,the number of detection planes will increase from 4 (in the present CSC region) or 8 (in the MDTs) to 16.

Both Micromegas and sTGC will provide precision tracking and triggering functionality, introducing a high level of redundancy and the means for sophisticated internal consistency checking. In addition, the NSW electronics, which consists of more than 8000 on-detector frontend, readout and trigger boards, uses a novel ASIC, the so called VMM chip custom developed for the upgrade and providing amplifier, shaper, discriminator, charge measurement as well peak detection and timing functionality. More than 50000 VMM chips will be installed in the system, to cover the approximately 2 million readout channels of the MM and sTGC chambers.

During the last eight months, chamber construction has advanced significantly in all production sites: Chile, China, Canada, Israel and Russia for the sTGC, and Germany, France, Italy, Greece and Russia for the Micromegas. Most of the chambers needed to complete the first of the NSWs, have already been built, albeit not yet all delivered to CERN. For the Micromegas in particular, the team found an instable HV behaviour in some of the chambers chambers and thus performed a number of dedicated tests holding the chambers at the development laboratories. In the past months, substantial progress has been made to efficiently tackle these issues and progress with the building of the detectors; especially in cases that the origin of this instability was due to low resistivity at local spots in some of the Micromegas readout boards. On the electronics side, all but one of the electronics components and cards have successfuly passed the Production Readiness Review and today most of the ASICs and several of the electronics cards are in production.

Activities at CERN ramped up drastically in the last months, and are now in full swing in buildings 899 (BB5), 180 and 191. A full NSW sector consists of two sTGC wedges and a Micromegas double wedge; for the first such sector, both parts are currently assembled and prepared for testing

In building BB5, the first micromegas chambers have arrived and double-checked for gas tightness as well as their HV behavior. Following these tests a fraction of the chambers is sent to the dedicated Gamma Irradiation Facility GIF++ in CERN's North Area, and further tested under different irradiation levels to ensure their quality and their ultimate performance. Upon successfully passing these tests, chambers are assembled into what is called a double wedge; the "Micromegas part" of each of the 16 detector sectors.

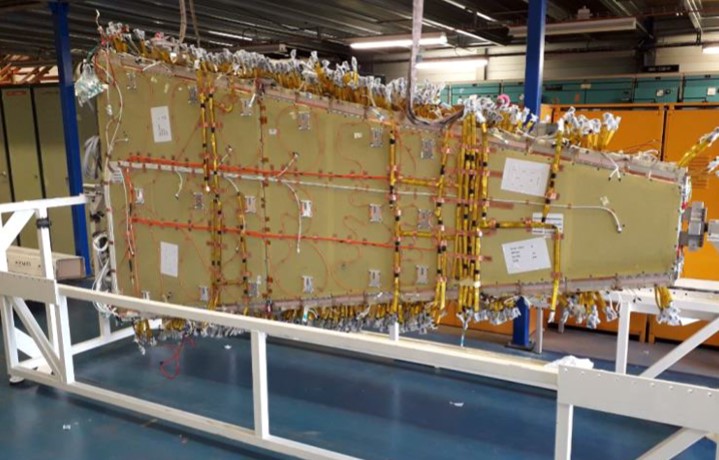

Literally hundreds of cables must be pre-installed in the Micromegas support structure. They are carefully routed to avoid breaching the stringent geometrical envelopes imposed by the very limited space for the installation of the NSW. Finally, the double wedge is equipped with its electronics, and undergoes a full readout test and a few days of data taking with cosmic rays.

The sTGC chambers have also arrived in building 180. They undergo similar reception tests, like the Micromegas, to spot any faults that may have incured during the transport procedure. All sTGCs are also checked at the GIF++ facility under high irradiation rates. Following these steps, each of the three chambers is assembled into the sTGC wedge. Wedge assemble is done by placing the sTGC chambers on a granite table, aligning them with great precision against a reference jigging, and then gluing a fiberglass support frame on top of them.

Once the operation is done on one side, the “half wedge” is rotated and the support frame glued to the other side. After this step, the wedge be handled without special vacuum tooling. Services are installed, and each wedge is then again tested for several weeks with the nominal gas mixture at full high voltage. Once electronics cards are available front end boards are installed and the cabling is finished.

Figure 1. Mechanical assembly of a sector. The sTGC wedges are visible on the outside, while the Micromegas double wedge is sandwhiched in between them.

Figure 2. A Micromegas double wedge, for a small sector, with all its electronics installed and under cosmic ray validation in BB5

Finally in building 191, the mechanical support structures for the NSWs have been completed. For the A-side one, a major effort went into pre-installing the many cables, fibers, cooling and gas pipes and was successfully completed in May 2019. The structure is now ready for receiving the different detector sectors. The commissioning team took over and equipped building 191 with a gas and cooling system to supply the NSW during tests; they installed the required power supplies, readout and HV allowing to operate up to 2 sectors simultaneously.

Figure 3: The two News Small Wheel structures, ready and waiting for the first detector sector to be installed.

A significant challenge for the team is to establish a smooth procedure for ensuring that a sector works properly, including the trigger path and thus guarantee a smooth operation. Several different approaches will be used, internal pulsing for the VMMs using pre-defined hits patterns, and verifying that they are reconstructed as trigger segments, localized scintillators triggered by cosmic rays and checking that the triggered muons are equally seen in both the MM and sTGC chambers and a full auto-trigger mode for the Micromegas.

Figure 4. The first completed Micromegas large sector double wedge. Large sectors can be installed only when all small sectors are in place. They will be stored therefore for the moment.

Figure 5. sTGC_wedges: Several assembled sTGC wedges during thei rHV and longterm gas test in building 180.

The NSW team plans to install the first sector in the next weeks. The results from these tests and the experience gained from its installation will be used for a system review planned for November. At that point, an assessment shall also happen on whether NSW-A will be ready for the planned installation in August next year; Regarding the NSW side C, ATLAS the team aims to install it during the next LHC year-end-technical stop that is scheduled to take place after the first year of Run-3 data taking.

Stay tuned for more developments…