The ALICE ITS upgrade: Pixels for quarks

Introduction

ALICE, the heavy-ion dedicated experiment at the LHC, will soon have enhanced physics capabilities with a major upgrade of the detectors, data-taking and data-processing systems which will improve the precision of the extracted characteristics of the high density, high temperature phase of strongly interacting matter, the quark-gluon plasma (QGP), together with the exploration of new phenomena in Quantum Chromodynamics (QCD).

To perform precision measurements of the strongly interacting matter, ALICE will focus on rare probes – such as heavy flavour particles, quarkonium states, real and virtual photons, and low-mass di-leptons – as well as the study of jet quenching and exotic heavy nuclear states. Observing rare phenomena requires very large data samples, which is why ALICE is looking forward to the increased luminosity provided by the LHC in the coming years. The interaction rate of lead ions during the LHC Run 3 is foreseen to reach around 50 kHz, corresponding to an instantaneous luminosity of 6×1027 cm–2s–1. This will enable ALICE to accumulate ten times more integrated luminosity (more than 10 nb-1) and hundred times larger data sample (about 1011 collisions) than what has been obtained so far. In addition, the upgraded detector system will have a better efficiency for the detection of short-lived particles containing heavy flavour quarks, thanks to improved precision of the inner tracking system (ITS), a silicon tracker based on monolithic pixel sensors.

During the Long Shutdown 2 (LS2), several major upgrades are being installed in ALICE: a new inner tracking system (ITS) with a new high resolution, low-material-budget silicon tracker, which extends to the forward rapidities with the new muon forward tracker (MFT), an upgraded time projection chamber (TPC) with gas electron multiplier (GEM) detectors along with completely new faster readout, new readout electronics for the muon spectrometer, a new fast interaction trigger (FIT) detector, and an integrated online-offline (O2) computing system to process and store the large data volume.

In this article we report on the upgrade of the ALICE Inner Tracking System (ITS): a major international R&D effort launched in 2011 that is scheduled to be installed in the ALICE cavern in June 2020.

The Upgraded ITS

The new ITS is an all-pixel silicon detector based on CMOS monolithic active pixel sensor (MAPS) covering the mid-rapidity (|h|<1.3) region. In the MAPS technology both the sensor for charge collection and the readout circuit for digitization are hosted in the same piece of silicon instead of being bump-bonded together. The chip developed by ALICE is called ALPIDE, and uses a 180nm CMOS process provided by Tower Semiconductor. With this chip, the silicon material budget per layer is reduced by a factor of seven compared to the previous ITS. The ALPIDE chip is 15x30 mm2 in size containing more than half a million pixels organized in 1024 columns and 512 rows. Its low power consumption (<40 mW/cm2) and excellent spatial resolution (~5 mm) are perfect for the inner tracker of ALICE.

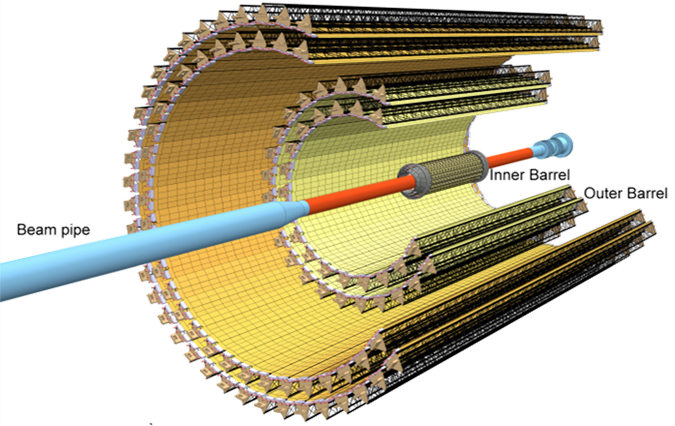

The ITS consists of seven cylindrical layers of ALPIDE chips summing up a total area of 10 m2 and 12.5 billion pixels. The pixel chips are installed on staves with radial distances ranging from 22 mm to 405 mm from the interaction point (IP). The beam pipe is also newly designed with a smaller radius of 18.6 mm, allowing the first detection layer to be placed closer to the IP at a radius of 22.4 mm compared to the presently 39 mm

The brand-new ITS detector will improve the impact parameter resolution by a factor of three in the transverse plane and by a factor of five along the beam axis. It will extend the tracking capabilities to much lower pT, allowing ALICE to perform measurements of heavy-flavour hadrons with unprecedented precision and down to zero pT. The new ITS will also enhance the readout capabilities, allowing data readout and recording at interaction rates in excess of 50 kHz, the expected Pb-Pb interaction rate at the LHC after Run 2. This increase in readout speed, together with the deployment of a new data acquisition system that will allow recording all collisions, translates to an increase by about two orders of magnitude in the collectible minimum-bias statistics compared to the present ALICE set-up.

The upgraded detector is the outcome of a well-coordinated global collaboration effort that brought together more than 35 institutes and research centres from 15 countries. Following an intense 5-year R&D programme, the successful prototyping and production of the different parts of the detector took place in 2017-2019 while the first components of the new ITS started arriving at CERN since summer 2018.

They are currently assembled and tested in Building 167 of CERN’s Meyrin site, where the new ALICE ITS is taking shape, preparing for the final phase of installation and commissioning starting from mid 2020.

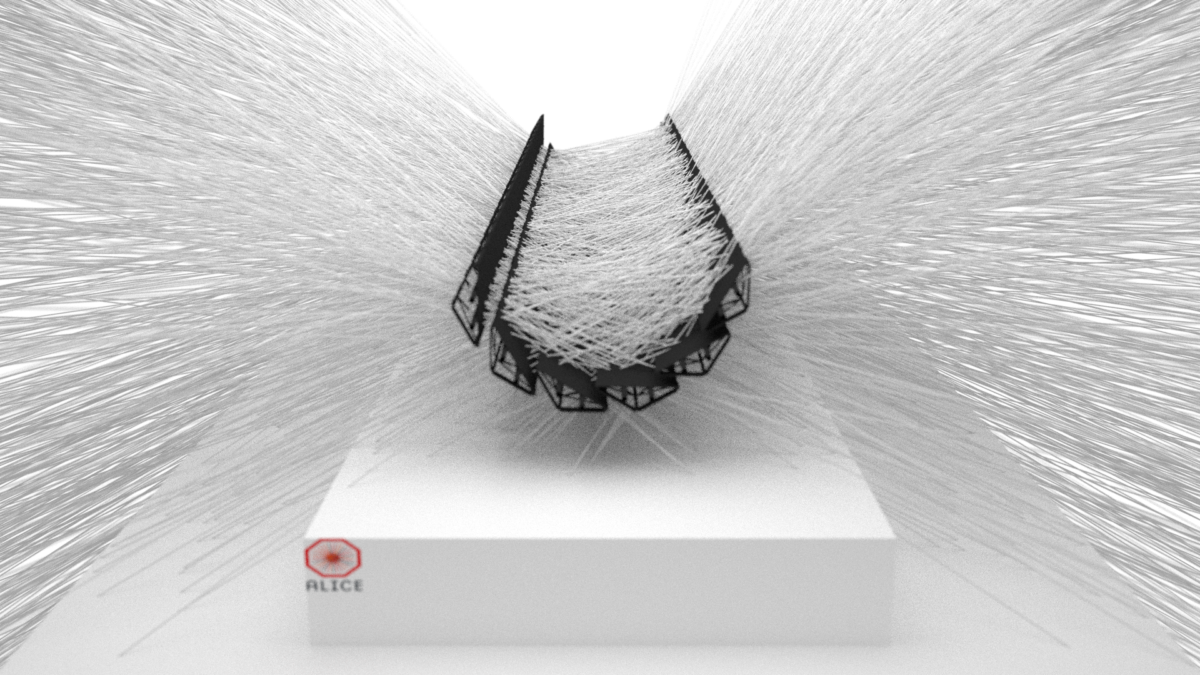

Figure 1. Picture showing the design of the new ALICE ITS and the different layers of the inner and outer barrel.

A new chip is born

The high level of vertexing and tracking performance expected from the upgraded ALICE inner tracking system (ITS) places tough demands on granularity and material thickness. To meet this challenge, ALICE has developed a new, dedicated monolithic active pixel sensor chip (MAPS), called ALPIDE, integrating both pixel sensor and read-out electronics in a single device.

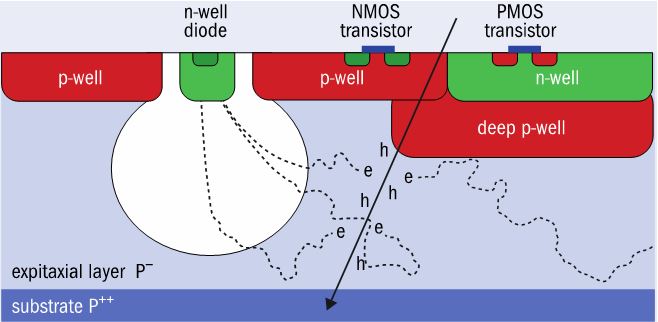

This 15 x 30 mm2 chip is the outcome of global collaboration. It is manufactured on a p-type substrate with a thin, high-resistivity epitaxial layer (see diagram) in a 180 nm CMOS process provided by Tower Semiconductor.

Figure 2. A schematic cross-section of CMOS pixel sensor used for the ALPIDE chip (ALICE ITS Upgrade TDR).

It includes a 512 x 1024 matrix of 29.24 x 26.88 mm2 pixel cells, together with analogue biasing, control, readout and interfaces. The signal sensing element is a diode typically 100 times smaller than the pixel cell. A charged particle crossing the sensor liberates free charge-carriers in the material by ionisation. Electrons released in the epitaxial layers diffuse laterally while remaining vertically confined. When they reach the depletion volume of a sensing diode (or are released directly inside it), they are swept to the diode contact by the electric field in the depletion volume. Holes are collected by the substrate and p-wells. The diode current induced by the carrier motion in the epitaxial layer is read out by the pixel front-end. A deep p-well layer (a deep p-type implant) shields the n-wells (n-wells implants) containing PMOS transistors from the epitaxial layer and prevents them from collecting signal charge.

This allows full CMOS (NMOS and PMOS) circuits within the pixel matrix and made the ALPIDE the first CMOS MAPS chip with a sparse readout similar to hybrid pixel detectors. ALICE is currently the only LHC experiment employing MAPS technology, presenting for the first time such a large-scale application if it. This technology had previously been used by the STAR experiment at the Relativistic Heavy-Ion Collider at Brookhaven National Laboratory.

Figure 3. Picture (left) and readout architecture (right) of ALPIDE, the chip developed for the ALICE ITS upgrade.

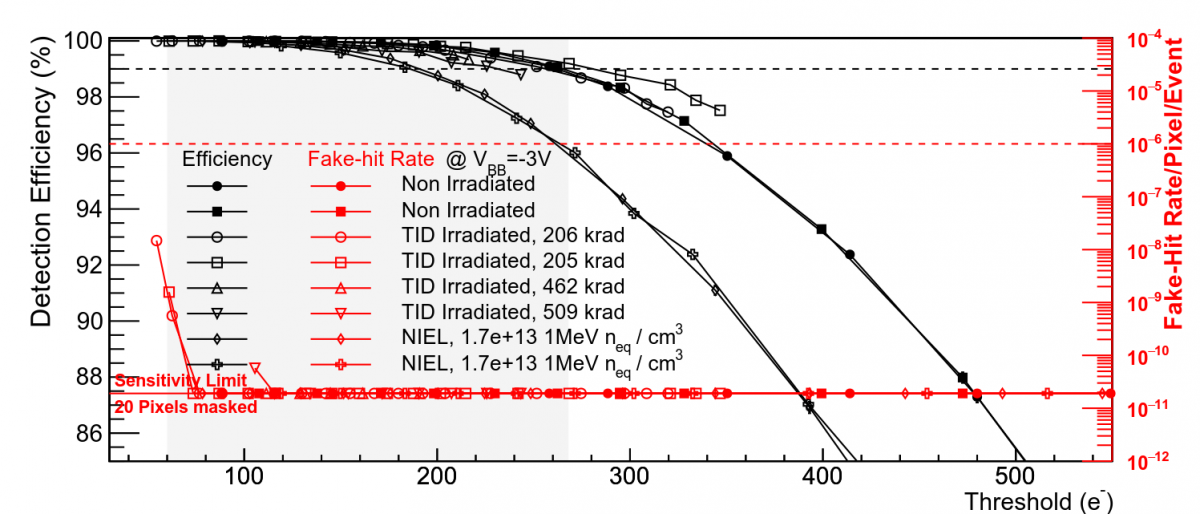

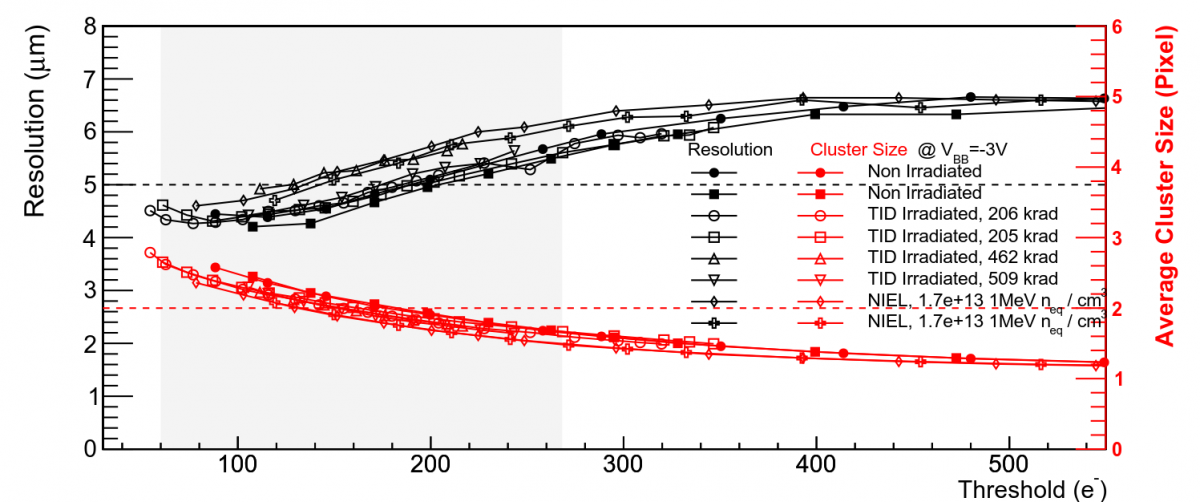

The outstanding performance of the ALPIDE chip can be seen in the plots of Figure 4(a,b). It is the outcome of a series of prototypes used to optimize every aspect of the circuit and a continuous interplay of the chip design team and another international effort to thoroughly characterize and qualify the prototypes, eventually involving more than ten institutes around the globe and carrying out beam tests at several facilities including the CERN PS and SPS.

The design effort finished in 2016 and immediate production started allowing the timely assembly and testing of detector modules that has been completed in May 2019.

Figure 4a. The left axis shows the detection efficiency vs. threshold for several ALPIDE chips, irradiated and non-irradiated. On the right axis, the fake-hit rate is reported. Dotted lines represent the design requirements: detection efficiency larger than 99% and a fake-hit rate below 10-6 (/pixel/event). It can be seen that the new chip offers a very large operational margin with only 10 masked pixels (of the total of 5x105 pixels). The high efficiency of 99% is retained even for a much lower fake-hit rate, compared to the design requirements, down to values of 10-11 (/pixel/event). The new ALPIDE chip offers very high operational margins even when the detector is radiated ten times higher compared to what is expected in the ALICE environment during the next runs of the LHC. (Nucl. Phys. A967 (2017) pp. 900-903).

Figure 4b. The left axis shows the intrinsic spatial resolution vs. threshold for several ALPIDE chips, irradiated and non-irradiated. The right axis shows the cluster size. The plot clearly shown that a large set of operational values (and thresholds) ALPIDE offers a spatial resolution of about 5μm (Nucl. Phys. A967 (2017) pp. 900-903).

A marvel of micro-engineering

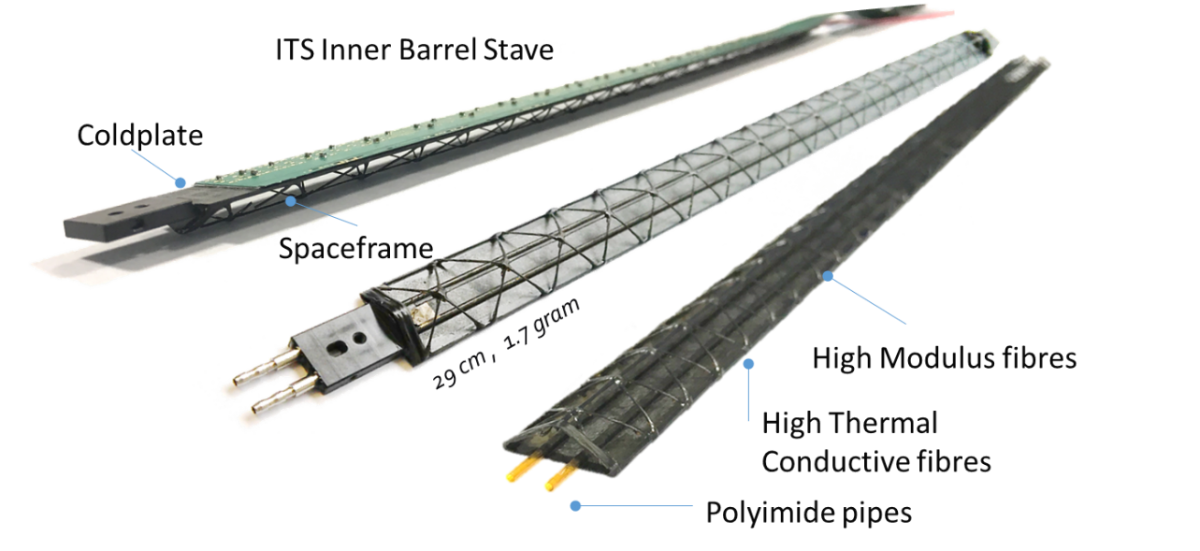

Upgrading the ITS posed a challenge for mechanical engineering. The structural support for the ALPIDE sensors should embed the cooling for the sensors, and at the same time minimize the material budget to ensure high performance. For that purpose, a new original design has been developed for the ITS stave, based on a record ultralight carbon structure with embedded micro-polyimide pipes for water-cooling at sub atmospheric pressure.

The structure is based on a thin plate, the so-called Cold Plate, obtained by an optimised lay-up of different high thermal conductive carbon plies, on which the ALPIDE sensors are glued. The Cold Plate incorporates a polyimide pipe, running along the entire stave length and back. This design enables getting the coolant inlet and outlet, at the same side of the detector that thanks to the design remains accessible.

The heat, dissipated by the ALPIDE sensors, is conducted into the cooling pipes via the carbon plate and is finally removed by the water flowing in the pipes. The polyimide pipes have been produced with very small diameters, down to 1mm, and a minimum wall thickness of 25 µm for the three innermost layers.

To ensure mechanical stability the Cold Plate is stiffened by the Space Frame, a light filament wound carbon structure with a triangular cross section. This concept applies both in the staves of the three innermost layers of the Inner Barrel (IB), 290 mm in length, and the staves of the four outer layers in the Outer Barrel (OB), up to 1475 mm. The implementation of each layer is tailored based on the different geometrical and thermal constraints. Thanks to these choices, an unprecedented light weight of 1,7 gram has been achieved for the IB stave structure including the cooling pipes.

The optimization of such a non-standard production process, for so lightweight composite structures, entailed an extensive prototyping phase through which the carbon plies lay-up and co-curing process with the polyimide pipes were tuned. The final design has passed the full cycle of thermal and structural qualifications and mass production (> 300 parts) was concluded in 2018.

Figure 5: Inner Barrel Stave fully assembled with IB module glued on the mechanical support. The support is constituted by a high thermal conductive carbon Cold Plate with embedded polyimide cooling pipes stiffened by a carbon filament winded Spaceframe.

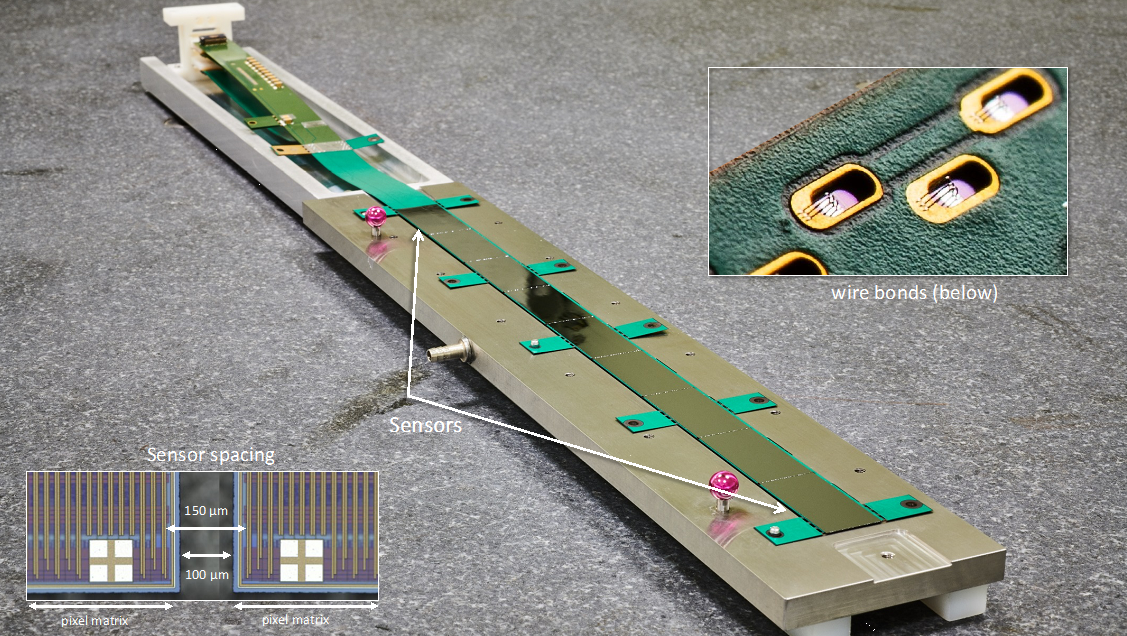

The staves of the Inner Barrel (IB) with a length of 290 mm are made of one module consisting of nine ALPIDE chips (see Fig.6).

Fig 6. Photograph of an Inner Layer Module. Insets show the spacing between adjacent chips and the interconnection to the flex printed circuit board via wire bonds. (Credits: ALICE collaboration).

The OB is divided into the two middle layers and the two outer layers sharing the same design but having different length, 843 mm and 1475 mm respectively. The half-stave at the middle of the OB consist of four modules whereas the outer layer of seven.

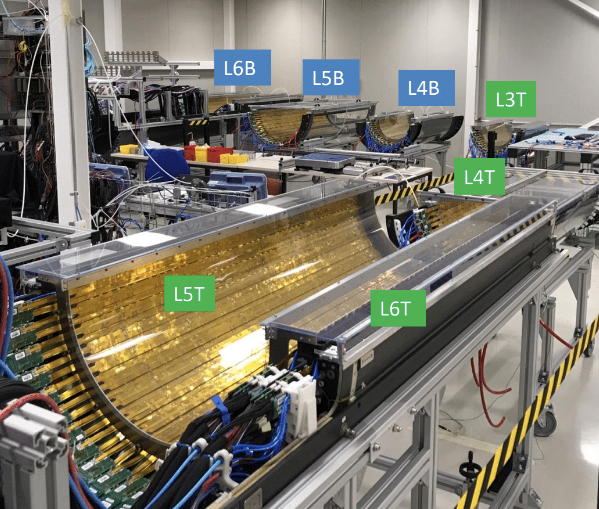

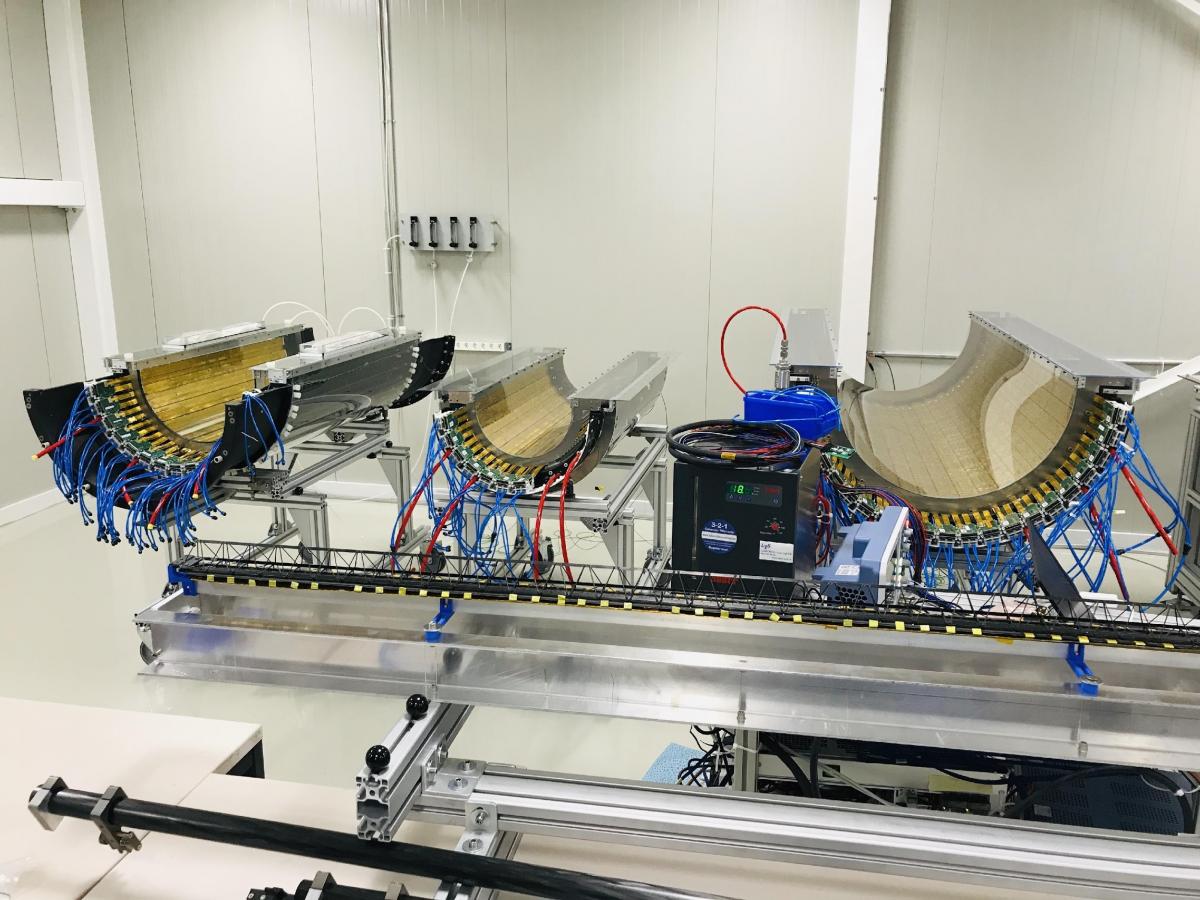

The staves are assembled in half layers and inserted in structural barrel shells, as shown in Figure 7 for the Inner Barrel and Figures 8a and 8b for the Outer Barrel. Three Half layers will make one half of the Inner Barrel, while four half-layers will make half of the Outer Barrel.

The Design of the ITS Barrels and global mechanics was further challenged by the new detector layout, with the services connected only at one side, and by a new installation requirement, that would allow for a immediate access to the ITS during the yearly LHC winter shutdown. This requirement excludes the possibility of displacing or dismounting the surrounding detectors.

Figure 7: The three Half-Layers of the Inner Barrel are constituted by the assembly of 24 stave. The Inner Barrel keeps in position the three innermost layers of the new ITS at two millimetres from the beam pipe. The Barrels ultralight composite structure, produced at CERN, fulfil the requirement of the new ITS in term of detector layout stability and accessibility.

A new installation strategy allows for the translation of the ITS detector, in halves, by approximately 3 m along the beam pipe. During the translation, the two ITS halves progressively approaches the final position with the innermost layer at a radial distance of only 2 mm from the fragile beryllium pipe of the LHC.

Figure 8a. Photo taken at the ITS assembly hall in Building 167 at CERN. Layers 5 and 6 for the top-half of the ITS Outer Barrel (L5T and L6T) have been assembled while Layers 4 and 3 are lining up for installation (L3T, L4T). Once assembled they will be mounted to build the full top-half barrel over the coming weeks. Moreover, in the background one can see Layers 4B, Layers 5B and Layers 4B ready for the assembly of the bottom half of the ITS outer barrel that is scheduled for October 2019.

Figure 8b. The photo shows Layers 4, 3 and 5 (from right to left) that together with Layer 6 will form the half Outer Barrel of the new ITS. The different modules arrived at CERN from labs around the world – signaling a strong international effort – and are currently been assembled.

Current status

The construction of all mechanical structures was completed last year. The first fully equipped inner barrel staves were produced in 2017 and tested at realistic operational conditions in heavy-ion collisions at CERN’s SPS while the stave production is expected to be completed later this September 2019. All the other main detector components (readout electronics, power distribution system, trigger, data acquisition, detector control) and services (power supplies, cooling plant) have been also produced and successfully tested.

The early availability of all services and detector components allowed to start the commissioning of the individual half-layers before they are assembled to form the two detector half-barrels (Inner and Outer) as shown in the above images. The results confirm the validity of the selected approach and the value of focused R&D on detector development.

Since last May, the collaboration has started testing the different detector components with cosmic rays simulating as close as possible the conditions of a real experiment. In a specially arranged area in Building 167 (CERN Meyrin site) teams of shifters control the various parameters of the detector and gather data that will help with the final optimization before the installation in the ALICE cavern. This activity has motivated the whole ITS collaboration to take part in this pre-commissioning phase. Owing to their strong support, plenty of test results have already been obtained that help us to understand and optimize the operational parameters of each subsystem and of the overall ITS performance. Moreover, these results allow to carefully check for any remaining issues that should be tackled before the final installation in the ALICE cavern next year.

Extremely low thermal noise vales of <6e have been verified on the detector, and, together with a threshold dispersion of ~20e, allow for operation at signal-to-noise ratios of 10 and above while staying >>99% efficient. These performance figures of the detector, going well beyond the original design requirements, can be exemplarily seen in Figure 9 below, showing the extremely low fake-hit rate of Half-Layer 0, which drops to below 10-10 (/pixel/event) after masking only 42 out of the 28 million pixels; a remarkable result.

Figure 9. Fake-hit rate measured on the six staves making the Half-Layer 0. It is plotted versus the number of pixels that are masked and shows that a very small fraction of pixels is responsible for most fake hits. Different colours correspond to pixels that fire with a given frequency. Masking of 42 pixels already lowers the fake-hit rate from 10-6 to 10-10 (/pixel/event). Pixels that fire only a few times can be partially attributed to cosmics. Note that the first division of each axis is linear, while the others are logarithmic.

The results confirm the soudness of the adopted technology, in terms of performance but also of reliability since the performance remained very stable over time.

In the past months, the team performed noise studies of the different detector elements, and also tested them using radioactive sources such as Sr-90. This method, that produces a radiography of the assembly, allows to quickly assess the correct functioning of the detector. These images contain a wealth of qualitative information, e.g. revealing the capacitors and overlapping areas of staves of the Inner Barrel (see Figure 10).

Figure 10. A Sr-90 hit map image taken with the half-layer 0 of the new ALICE ITS, projected onto the position of the chips in 3D.

Owing the overlaps of the ITS geometry, already a single half-layer has a small but non-negligible cross-section for tracks to cross three sensors and hence produce a track with three points. With this observation, the team has been collecting a large sample of cosmic particle tracks since the first half-layer has been connected to the readout at a rate of one cosmic track per minute (Figure 11 shows ~1400 of them). This data is used to verify the time alignment in readout and reconstruction of events, to verify the geometrical position of the staves, and will successively (including more detector layers) serve for the ultra-precise spatial alignment needed between the different layers of the new ITS.

Owing the overlaps of the ITS geometry, already a single half-layer has a small but non-negligible cross-section for tracks to cross three sensors and hence produce a track with three points. With this observation, the team has been collecting a large sample of cosmic particle tracks since the first half-layer has been connected to the readout at a rate of one cosmic track per minute. This data is used to verify the time alignment in readout and reconstruction of events, to verify the geometrical position of the staves, and will successively (including more detector layers) serve for the ultra-precise spatial alignment needed between the different layers of the new ITS.

Figure 11. 3D view of the first ~1400 cosmics taken. The pictures clearly show the effect of a non-uniform (esp. angular) acceptance due to the requirement of three points on a track, while using only one detection layer.

Conclusion

Thanks to a well-structured R&D programme that attracted international collaborations and an intense period of testing and commissioning the ALICE ITS is taking shape in Building 167. The new detector is part of the upgraded ALICE which during the next runs of the LHC will provide new set of more precise measurements to meet the long-term goals of the ALICE collaboration in the study of QCD and the characterization of the Quark-Gluon Plasma.

The upgrade of the ALICE ITS will not only boost the physics capabilities of the ALICE experiment but as we discussed has advanced a number of technologies beyond the state of the art. The results of this R&D effort currently find applications both in high-energy physics (i.e. sPHENIX at RHIC, BNL and the Inner Tracking System of the MPD experiment in NICA at JINR) but also in other fields. Perhaps one of the most topical examples is medical tracking with the development of pCT detectors for application in hadron therapy. The fast monolithic pixels developed for the ITS upgrade can improve significantly the accuracy of the image with regard to the present state of the art while reducing the exposure time for patients.

An enormous amount of effort has gone into the new ITS over the past years, strengthening collaboration between CERN and institutes from around the world. The fruits of those labours can now be seen while the final installation of the detector in summer 2020 will pave the way for new discoveries that could open up a whole new field of knowledge.

The author would like to thank the members of the ALICE ITS upgrade project for their remarks and extend a special acknowledgment to Luciano Musa, Corrado Gargiulo and Magnus Mager for invaluable discussions and contributions that helped shaping the final form of this article.